The exploration of abrasive materials encompasses a range of substances each engineered to fulfill distinct roles across a multitude of industries. From natural abrasives like garnet to synthetic options such as silicon carbide, the choice of abrasive material is pivotal in determining the efficiency, finish quality, and cost-effectiveness of surface treatment processes. As industries strive for higher precision and lower environmental impact, the selection and application of these materials become increasingly critical. The nuances of these choices and their implications on both performance and environmental sustainability pose an intriguing point of discussion, particularly when considering the technological advancements that continually reshape this field.

Abrasives constitute materials engineered to wear down or refine the surfaces of other materials through friction. These abrasive materials are pivotal in the surface treatment and material processing sectors. They are designed to be harder than the surfaces they modify, which allows them to effectively alter the appearance, texture, or performance of a material without significant degradation to the abrasive itself.

In industrial uses, abrasive applications vary widely and include grinding, cutting, polishing, and sanding. Each application employs abrasives in different forms like grinding wheels, sandpapers, and honing stones, tailored to specific tasks.

For instance, in the manufacturing of metal products, abrasives are used to smooth edges and surfaces to enhance the product's functionality and aesthetic appeal. Similarly, in the woodworking industry, abrasives are essential for achieving a fine finish on furniture and other wooden products.

The versatility and efficacy of abrasive materials in surface treatment and material processing make them indispensable tools in virtually every manufacturing industry. From automotive to aerospace and from construction to electronics, the role of abrasives is fundamental in producing finished products that meet precise specifications and high-quality standards.

Understanding the properties of abrasive materials is crucial for selecting the right type for specific applications. The characteristics of abrasives dictate their performance in various tasks, from heavy-duty grinding to fine polishing. Each property contributes distinctively to the functionality and suitability of the abrasive for specific operations.

Other essential properties include abrasive durability and sharpness. Durability influences the longevity and wear resistance of the abrasive, making it cost-effective for prolonged use. Sharpness, on the other hand, determines the cutting efficiency, which is crucial for maintaining productivity and achieving desired surface finishes.

Understanding these properties helps in making informed decisions that optimize both performance and cost.

Abrasives find extensive applications across various industries, primarily due to their ability to alter physical surfaces. They are employed in surface cleaning, shaping and sizing objects, and in processes that require precise material separation.

Additionally, abrasives play a crucial role in polishing and finishing, enhancing the functional and aesthetic qualities of products.

Removing dirt, stains, and other contaminants from surfaces frequently utilizes various types of abrasive materials. These materials play a crucial role in surface preparation, ensuring that surfaces are primed for painting or further treatments.

Abrasive blasting, for instance, is a common method for metal cleaning and rust removal, providing a smooth, clean surface that improves adhesion of coatings and prevents rapid deterioration.

Paint stripping and graffiti removal are additional applications where abrasives prove indispensable. They efficiently remove unwanted layers and defacements from surfaces, restoring them to their original state without causing significant damage to the underlying material.

Here are some key benefits of using abrasives in surface cleaning:

Abrasives, through their mechanical action, strip away contaminants and coatings, which is essential for maintaining the integrity and aesthetics of structural materials. Consequently, the careful selection of the appropriate abrasive material is crucial to maximize cleaning efficacy while minimizing surface damage.

In the realm of abrasive applications, shaping and sizing the particles is critical for optimizing their performance in various tasks. Particle size plays a fundamental role in determining the suitability of abrasives for specific uses, ranging from coarse 4 grit particles down to ultra-fine 900 grit powders. These variations allow for everything from heavy material removal to high precision polishing required in optical lenses.

Crushing methods significantly influence the grain shape and, consequently, the cutting action and strength of the abrasive grains. Heavy crushing pressures typically produce sharp, splintery grains that penetrate materials quickly and are ideal for tasks where frequent resharpening is beneficial. This type of grain is prevalent in coated abrasive products where sharp edges enhance cutting efficiency.

Strength analysis of these grains reveals that while sharp, splintery grains are effective for swift material removal, they tend to have lower structural integrity. Conversely, more robust, regularly shaped grains withstand higher pressures and are preferred for grinding large amounts of material. Their shape ensures longevity and sustained performance under strenuous conditions, balancing the trade-off between sharpness and strength to meet diverse industrial needs.

Separating materials precisely and efficiently is a critical application of abrasive technologies in various industries. Abrasives play a pivotal role in cutting applications, where the objective is not merely to cut, but to do so with a high degree of accuracy and minimal material loss. The effectiveness of abrasives in such applications is heavily dependent on the particle size and the grinding techniques employed.

In industries such as metal fabrication and stone masonry, abrasives are utilized to cut through hard materials. This process requires abrasives that can handle significant material removal without causing undue surface roughness. The precision in cutting ensures that the integrity of the material is maintained, which is crucial for the subsequent manufacturing steps or final applications.

Key aspects that illustrate the importance of abrasives in separating applications include:

While abrasive materials are essential for cutting and shaping, they are equally crucial in polishing and finishing applications to achieve smooth, refined surfaces. The choice of abrasive selection plays a pivotal role in the effectiveness of polishing techniques and finishing methods. Each abrasive material, from finer grits to coarser ones, is tailored to specific types of surface preparation and material removal, ensuring the desired finish is achieved efficiently.

In the realm of polishing techniques, abrasives are used to progressively smooth the surface of the workpiece. This is often done through a series of steps, starting with a coarser abrasive to remove major imperfections and gradually moving to finer abrasives, which refine the surface to a high shine or smooth matte finish. The transition between different abrasives must be managed meticulously to avoid surface damage and to achieve a uniform finish.

Similarly, finishing methods involve a careful application of abrasives to enhance the aesthetic or functional quality of a surface. Whether preparing a metal part for painting or achieving a mirror finish on a piece of jewelry, the proper abrasive selection, aligned with the correct technique, is critical. This ensures that the surface preparation is optimal, leading to superior durability and appearance of the final product.

Abrasives play a crucial role in various industrial sectors. This includes automotive aftermarket processes such as sanding, polishing, and finishing, manufacturing activities like metalworking and tool sharpening, and construction tasks focused on surface preparation and finishing. The versatility of abrasives extends much further into specialized fields where precision and meticulous finishing are paramount.

Abrasives are essential in aerospace for material finishing and component fitting, ensuring aerodynamic smoothness and structural integrity in aircraft manufacturing. In electronics, abrasives are used to polish semiconductor wafers and other components, contributing significantly to the miniaturization and efficiency of electronic devices. In the medical device industry, abrasives are crucial for finishing intricate instruments and devices, ensuring their functionality and compliance with stringent health standards.

Further demonstrating their industrial significance, abrasives are integral in woodworking, refining surfaces and sharpening tools to enhance both aesthetics and functionality. In jewelry making, abrasives are used to polish gems and metals, bringing out their luster and appeal. This wide array of applications underscores the indispensable nature of abrasives in modern manufacturing and maintenance processes across diverse industries.

Using abrasives offers significant advantages, including increased efficiency and precision in material processing across various industries. One of the primary benefits is cost efficiency and increased productivity. Abrasives enable faster material removal, which speeds up production times and reduces labor costs. This efficiency does not come at the expense of quality; in fact, the use of advanced abrasive materials ensures improved surface quality, thereby minimizing the need for rework and further finishing processes.

Moreover, the precision offered by modern abrasives leads to consistently accurate results, essential in industries where exacting standards are the norm. This enhanced precision, coupled with the uniformity of results, ensures that products meet stringent quality controls, reducing waste and further driving cost efficiencies.

Additionally, abrasives are designed to be tough and durable, which contributes to longer tool life and reduced maintenance costs. This durability is not only beneficial economically but also environmentally. Many abrasive products are now made from recycled materials or designed for reusability, aligning with eco-friendly and sustainable solutions in industrial processes. These sustainable practices not only help in reducing the ecological footprint but also support industries in meeting environmental compliance and sustainability goals.

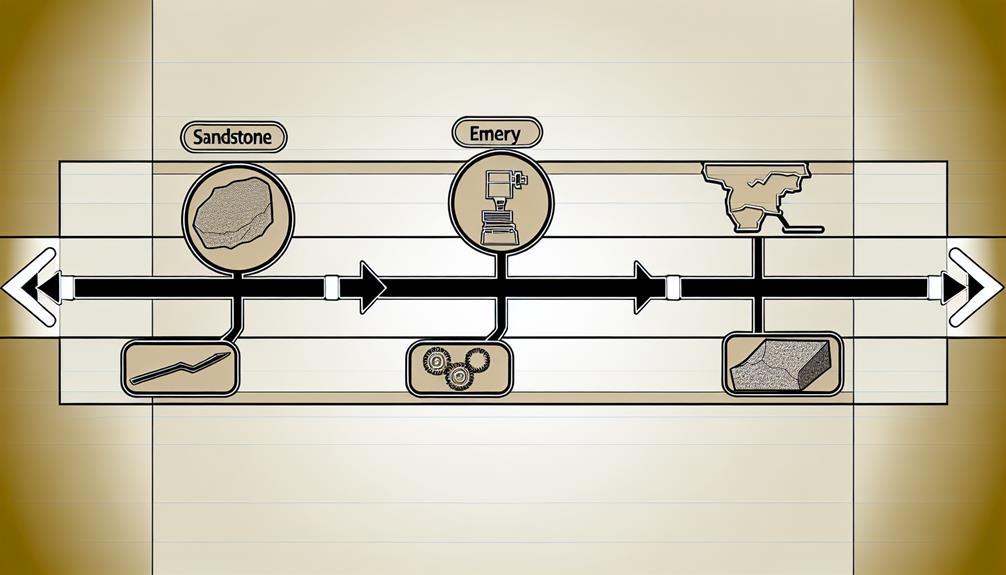

The origins of abrasive materials trace back to prehistoric times when early humans used hard stones to shape tools and weapons. Over the centuries, this practice evolved significantly, reflecting major historical developments and manufacturing advancements. Ancient civilizations, such as the Egyptians, utilized abrasives to polish precious items, indicating early forms of abrasive innovation.

By the Middle Ages, more structured methods to affix abrasive grains on backings were documented, illustrating the material evolution and its impact on the craft industries.

Key milestones in the history and development of abrasive materials include:

These advancements have had a profound industry impact, fostering new technologies and increasing the efficiency of manufacturing processes.

The ongoing evolution of abrasive materials continues to play a crucial role in both historical and modern industrial applications.

Abrasive materials are categorized broadly into natural and synthetic types, each serving distinct purposes across various industries.

Natural abrasives, such as diamond, garnet, and corundum, are mined from the earth and offer unique properties for specific applications.

Synthetic abrasives, on the other hand, are engineered to provide consistency and efficiency in performance, with examples including silicon carbide and aluminum oxide.

Natural abrasives, such as emery and garnet, have been utilized for centuries due to their hardness and availability.

Emery is known for its robustness and is commonly used in abrasive applications where strength is paramount.

Garnet, on the other hand, offers a different profile, being favored for its natural sharpness and relatively low dust production during cutting or polishing processes.

Emery, a naturally occurring abrasive, is composed of fine-grained corundum mixed with other minerals such as magnetite and hematite.

This substance continues to be integral in manufacturing and metal finishing processes.

Garnet is a significant natural abrasive that offers distinct advantages in waterjet cutting and sand blasting applications. Known for its hardness and durability, garnet properties make it ideal for precise cutting and efficient material removal.

Garnet usage extends to surface preparation due to its low dust emission. The benefits of garnet include cost-effectiveness and recyclability, enhancing its appeal in various industrial garnet applications.

Synthetic abrasives, including Aluminum Oxide, Silicon Carbide, Ceramic, and Zirconium, are engineered materials designed for specific applications across various industries.

These abrasives are known for their durability and sharpness, making them ideal for tasks requiring high levels of material removal and surface finish accuracy.

Each type offers unique properties, such as hardness and thermal resistance, catering to the needs of both heavy-duty industrial applications and precision work.

Aluminum Oxide, a manufactured synthetic abrasive, is renowned for its durability and versatility across various applications.

Silicon Carbide is a highly friable synthetic abrasive. It is distinct for its sharp, needle-like grains that enhance its cutting efficiency. It excels in finer sanding tasks and effective paint removal.

Ideal for rubbing out film finishes, including lacquer and shellac, Silicon Carbide is primarily utilized on waterproof paper. This abrasive is particularly adept at cutting through hard materials such as metal, fiberglass, and plastic.

Moving beyond Silicon Carbide, another significant synthetic abrasive is Ceramic, known for its durability and toughness. Ceramic abrasives offer several advantages:

These properties make ceramic an ideal choice in high-stakes industrial environments.

Zirconium oxide is a prominent synthetic abrasive known for its exceptional durability and fine grinding capabilities. Its properties include high thermal stability and resistance to wear, making it ideal for aggressive material removal in various industries. This abrasive is favored in applications within the aerospace and automotive sectors. The manufacturing process of zirconium oxide ensures consistent quality and performance in demanding environments.

Abrasives are utilized in various forms depending on their intended function and the surface they are meant to modify. Bonded abrasives are typically used in precision grinding and cutting, forming tools with rigid shapes such as grinding wheels.

Coated abrasives, which are grains attached to a flexible backing like sandpaper, are ideal for smoothing or finishing surfaces.

Loose abrasives, such as polishing compounds, are used for delicate surface refinement.

In the realm of bonded abrasives, grinding wheels and segments are primarily utilized for material removal and surface preparation. These tools are pivotal in various industries, from metal fabrication to construction, due to their effectiveness in shaping and finishing materials. The effectiveness of bonded abrasive wheels largely depends on the abrasive bonding and the quality of the bonding process.

Bonded abrasives consist of abrasive grains that are closely held together using a bonding material. The bonding technology ensures that grains are distributed uniformly, providing consistent performance throughout the life of the abrasive tool. The specific characteristics of the bonded materials, such as hardness and fracture toughness, dictate their suitability for different applications.

Key aspects of bonded abrasives include:

Understanding these elements can greatly enhance the selection process for bonded abrasive wheels, ensuring optimal performance and longevity in demanding material removal and surface preparation tasks.

Coated abrasives, such as sandpapers and belts, are essential tools for surface finishing and material shaping across various industries. These abrasives are made by fixing abrasive materials onto a backing material, typically paper or cloth. The benefits of coated abrasives include flexibility, uniformity of abrasive surfaces, and the ability to be used on a variety of shapes and materials.

Sandpaper applications range from smoothing to removing old paint, while belt grinding provides an efficient method for heavy-duty material removal and surface preparation. Both applications highlight the versatility and effectiveness of coated abrasives in achieving desired surface finishing results.

Here's a concise table to illustrate common uses and benefits:

| Application | Benefit |

|---|---|

| Sandpaper on wood | Smooths and prepares surfaces |

| Belt grinding on metal | Quickly removes material and finishes surface |

| Sandpaper on automotive bodies | Removes paint and smooths for repainting |

Coated abrasives play a pivotal role in numerous processes where precision and finish are critical. Their widespread use in metalworking, woodworking, and automotive industries underscores their importance in achieving fine and tailored surface finishes, demonstrating the inherent value of these abrasive systems.

Loose abrasives, such as polishing compounds and media for tumbling, are integral in processes that require fine surface finishing and cleaning. These materials are chosen for their flexibility and effectiveness in smoothing and refining a variety of surfaces.

Loose abrasives are primarily used in several key applications:

Selecting the appropriate abrasive requires careful consideration of several key factors, including friability, grit size, coating type, and backing material. When undertaking abrasive selection, it is crucial to assess material compatibility to ensure that the abrasive will not damage the workpiece. This involves choosing the right grit size and type based on whether you need more aggressive material removal or a finer finish. Surface preparation needs can also dictate the choice of abrasives, particularly in how the abrasive interacts with the material being processed.

Efficiency and effectiveness are vital, as the chosen abrasive should provide a balance between fast material removal and achieving the desired surface quality without excess waste or energy consumption. Longevity and durability are also significant, as selecting an abrasive with appropriate friability and backing material can influence the lifespan of the abrasive and the consistency of its performance.

| Factor | Consideration |

|---|---|

| Friability | Choose based on desired longevity and cutting action |

| Grit Size | Match with material hardness and required finish |

| Coating & Backing | Decide between open-coat for less clogging or closed-coat for uniform scratch patterns |

Yes, abrasive materials can often be recycled or reused. This practice not only contributes to sustainability efforts but also offers cost savings and reduces environmental impact. Recycling options and reusability benefits are significant.

Yes, eco-friendly abrasives are available, offering sustainable options like biodegradable alternatives. These green abrasive solutions minimize environmental impact and provide eco-friendly choices for various industrial applications, aligning with broader environmental sustainability goals.

Seasonal changes, painting a landscape of fluctuating temperatures and varying humidity, directly influence abrasive effectiveness. Moisture levels and weather conditions can alter their physical properties, impacting performance in different environmental settings.

When using abrasives, it is critical to ensure proper ventilation, wear eye and skin protection, maintain equipment regularly, and participate in training programs to prevent accidents and promote a safe working environment.

Abrasives impact machinery durability by affecting wear resistance, potentially shortening the lifespan of equipment. Proper use of abrasives can enhance performance efficiency and reduce maintenance costs through improved preservation of machinery components.

In conclusion, the journey of abrasive materials illustrates a relentless pursuit of excellence in various industries. This evolution mirrors the meticulous craftsmanship of a sculptor transforming marble into a masterpiece. The strategic selection and application of these materials illuminate paths to innovation.

Embracing the right abrasives ensures the realization of potential in processes, echoing the transformative power of human ingenuity across centuries.

GINGONG in China offers high-quality diamond polishing and edge grinding tools alongside ceramic machinery accessories. Our integrated solutions cater to individual needs, ensuring optimal performance and efficiency. We lead the industry in ceramics polishing, emphasizing effectiveness, cost control, and environmental sustainability. With "Sanmo" machines and meticulous attention to detail, GINGONG delivers top-notch abrasive products, setting the standard for excellence.

Contact us for a free quote of your ideal abrasive grinding wheel!