In the realm of ceramic production, the mastery of lappato abrasive techniques holds a pivotal role in achieving impeccable finishes and precise outcomes.

Understanding the nuances of lappato abrasives goes beyond surface-level knowledge; it delves into the intricacies of material composition, machinery calibration, and the art of achieving a flawless lappato finish.

As we embark on this exploration of lappato abrasives in ceramics, we uncover a world where precision meets creativity, where the right tools can transform a piece from ordinary to extraordinary.

What distinguishes a Lappato abrasive from traditional tools in the realm of ceramic and stone surface finishing lies in its specialized composition and unique capabilities.

Lappato abrasives are crafted with diamond resin, a key feature that sets them apart from conventional abrasives. This infusion of diamond resin enhances the abrasive's effectiveness in shaping and refining ceramic and stone surfaces, particularly in tile production.

The primary objective of using Lappato abrasives is to achieve a specific surface finish known as the lappato finish, which requires precision and expertise in surface polishing methods.

When considering abrasive selection criteria for ceramic honing processes, the diamond resin characteristics play a crucial role in determining the tool's performance and the quality of the finish. Understanding the intricate details of Lappato finish techniques is essential for mastering the art of surface finishing in ceramics and stones.

The essence of the lappato finish lies in its unique blend of glossiness and texture, elevating ceramic tiles with a distinctive aesthetic appeal. This finish is achieved by carefully balancing a glossy surface with a textured feel, creating a sophisticated look that is neither fully polished nor entirely matte. Ceramic tiles treated with a lappato finish exhibit a luxurious sheen while also offering a tactile dimension that adds depth and character to the surface. Achieving this delicate balance requires the use of precise abrasive tools and techniques. Diamond lappato abrasives are instrumental in creating this finish, allowing for controlled abrasion that results in the desired surface texture and glossy appearance. By employing precision techniques, craftsmen can transform ordinary ceramic tiles into exquisite pieces that exude elegance and style.

Related Article: Diamond Lappato Abrasive: Precision in Ceramic Surface Treatment

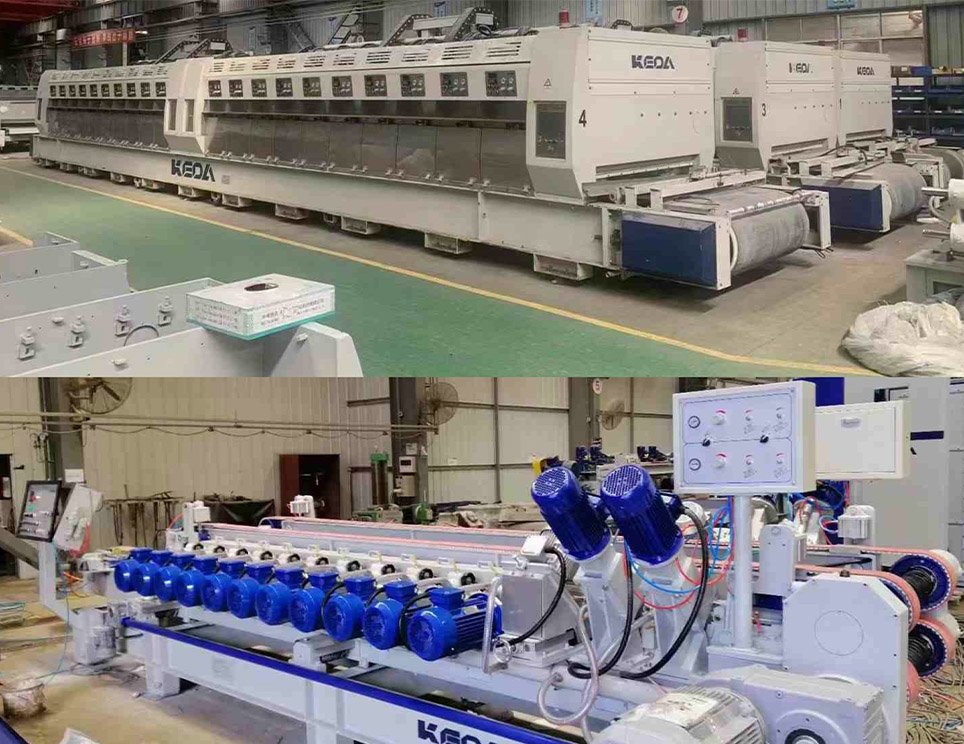

A crucial component in the production process of ceramic tiles, the line polishing machine is a specialized equipment designed to achieve a smooth and glossy finish on the tile surfaces.

These machines play a vital role in ceramic processing, particularly in the final stages after firing and glazing. Line polishing machines employ various polishing techniques utilizing abrasive applications to create the desired surface finishes.

Typically, these machines consist of multiple polishing heads or discs mounted on a conveyor belt, through which the tiles pass to undergo the polishing process.

The choice of abrasive material, such as diamond abrasives, silicon carbide abrasives, or alumina abrasives, influences the efficiency of the machine in achieving the desired results.

The machine efficiency is crucial in ensuring consistent and high-quality surface finishes on the ceramic tiles, making them suitable for applications like bathrooms and kitchens.

Mastering the operation of line polishing machines is essential for producing top-notch ceramic tiles with a polished and glossy appearance.

Related Article: Elevate Your Manufacturing:The Science Behind The Ceramic Grinding Machine

Diamond lappato abrasives function by efficiently removing material from ceramic surfaces using their diamond resin components. The diamond resin ensures secure bonding and contributes to achieving a glossy finish through fine polishing.

To enhance performance and prevent overheating, water lubrication is frequently utilized during the abrasive process.

Utilizing advanced abrasive technology, Lappato abrasives with diamond components efficiently remove material from ceramics, showcasing their effectiveness in the ceramic industry. The material efficiency of diamond removal in these abrasives is attributed to their superior abrasives performance and effective bonding with the ceramic surface.

When used with water lubrication, diamond Lappato abrasives enable optimal polishing, ensuring a smooth and refined finish. Additionally, these abrasives facilitate a semi-polishing transition, enhancing the glossiness of the ceramic surface.

Apart from their performance benefits, diamond Lappato abrasives also offer eco-friendly advantages due to their high durability, making them a sustainable choice for material removal in ceramic processing.

In the realm of ceramic processing, the effectiveness of diamond Lappato abrasives lies in their ability to establish a secure bonding with diamond resin, showcasing their intricate working mechanism.

How can water lubrication enhance the operational efficiency and effectiveness of diamond Lappato abrasives in ceramic processing? Water lubrication benefits play a crucial role in optimizing the performance of Lappato abrasives by providing efficient cooling and lubrication during the grinding process. This method not only enhances the surface smoothness techniques but also ensures precise Lappato abrasive application on ceramics. By incorporating water cooling advantages, the abrasives can operate at their peak levels, resulting in significant efficiency and performance enhancements. This technique enables finer control over the grinding process, leading to superior outcomes in terms of surface finish and overall quality.

Water lubrication plays a crucial role in optimizing the efficiency and effectiveness of diamond Lappato abrasives in ceramic processing. It extends to semi-polishing techniques where understanding various polishing methods is essential. This phase requires a meticulous approach to achieve specific surface finishes and gloss levels. To master semi-polishing with diamond Lappato abrasives, consider the following:

Lappato abrasive for ceramics offers numerous benefits, including high glossiness and an instant polishing effect, making it an excellent choice for achieving a superior finish.

Additionally, its eco-friendly and non-staining properties ensure a safe and sustainable option for ceramic processing.

With stable quality and outstanding abrasiveness, Lappato abrasive stands out as a reliable and efficient solution for ceramic manufacturers.

Achieving a superior level of glossiness and a near-instantaneous polishing effect are key advantages of utilizing Lappato abrasive for enhancing ceramic surfaces. When focusing on high glossiness and instant polishing effects, it is essential to consider the following:

When considering the advantages of Lappato abrasive for ceramics, one notable benefit lies in its safe-to-use properties and eco-friendly nature. This abrasive offers eco-friendly alternatives, promoting sustainable solutions in the ceramics industry. Manufacturers embracing Lappato abrasive contribute to green manufacturing practices, opting for environmentally safe options that align with earth-conscious innovations. The use of Lappato abrasive not only ensures a high-quality finish but also demonstrates a commitment to environmentally responsible choices. Below is a table showcasing the eco-friendly aspects of Lappato abrasive for ceramics:

With its superior abrasive properties, the Lappato abrasive enhances the precision and quality of ceramic finishes.

The Lappato abrasive's exceptional performance in polishing techniques not only guarantees a high level of material removal but also ensures that ceramic surfaces attain a remarkable smoothness, making it a top choice for professionals who prioritize control and precision in their work.

The exceptional non-staining property of the Lappato abrasive further solidifies its reputation as a versatile choice for ceramic professionals seeking impeccable surface finishes. Its impressive stain resistance ensures that the ceramic surfaces maintain their pristine look over time with minimal effort. By following simple maintenance tips and employing effective cleaning techniques, such as regular dusting and gentle wiping with a damp cloth, the color options available in Lappato finishes can remain vibrant for years. Additionally, sealing methods can be applied to enhance the longevity of the finish and protect against potential stains. This non-staining characteristic of Lappato abrasive not only provides aesthetic benefits but also eases the maintenance burden for users.

An essential attribute of the Lappato abrasive for ceramics is its consistent and reliable quality, ensuring superior results in surface finishes for discerning professionals. This stability is achieved through meticulous quality control measures and precision engineering, guaranteeing consistent performance with each use.

The material stability of the abrasive further enhances its longevity assurance, providing professionals with a tool they can rely on for extended periods without compromising quality. The precision engineering behind the Lappato abrasive ensures that it maintains its effectiveness throughout its lifespan, giving users control over their finishing processes with confidence.

Ultimately, the stable quality of the Lappato abrasive sets a high standard in the industry for reliability and performance.

Meticulously engineered to withstand prolonged use in demanding ceramic surface finishing applications, the Lappato abrasive exhibits exceptional durability, setting a new standard for longevity and performance in the industry. Its improved strength ensures long-lasting performance, even under intense pressure.

The enhanced resilience of the Lappato abrasive allows it to maintain its superior endurance over time, making it a reliable choice for professionals seeking extended lifespan from their abrasives. With these qualities, users can have confidence in the durability of the Lappato abrasive, knowing that it can endure the rigors of demanding ceramic surface finishing tasks without compromising on quality or performance.

Engineered to offer a range of versatile finishing options, the Lappato abrasive for ceramics provides professionals with a comprehensive solution for achieving diverse surface textures and finishes. The benefits of using this abrasive extend beyond traditional techniques, offering professionals greater control over the final appearance of their ceramic pieces.

Key benefits include:

These features provide unparalleled design flexibility, ensuring that every ceramic piece stands out with its own distinctive look.

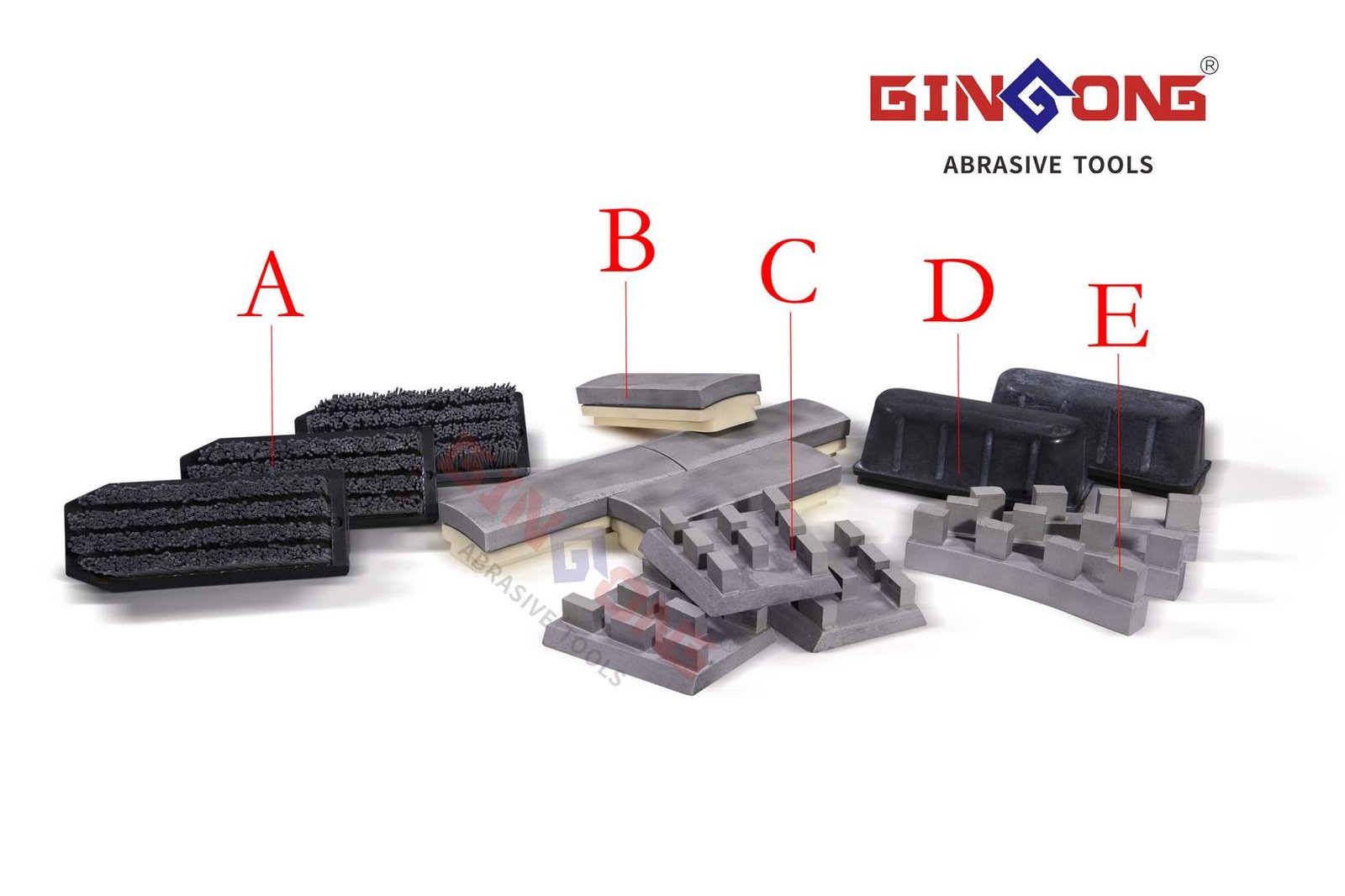

In the realm of Lappato abrasive for ceramics, various types stand out for their distinct characteristics and applications.

The Diamond Lappato Abrasive, Silicon Carbide Lappato Abrasive, and Alumina Lappato Abrasive are among the key players in this field.

Each type offers unique features that cater to different needs and preferences within the ceramics industry.

The application of diamond lappato abrasive in ceramics manufacturing showcases unparalleled efficiency and precision in achieving desired surface finishes. When considering diamond lappato abrasive, it is crucial to understand:

This abrasive type requires expertise in surface preparation, utilization of diamond tools, and knowledge of abrasive applications to optimize ceramic finishes effectively.

The use of diamond lappato abrasive offers a level of control and finesse that is unmatched in the industry, making it a preferred choice for achieving superior ceramic surface qualities.

Related Article: Diamond Lappato Abrasive: Precision in Ceramic Surface Treatment

A notable alternative to diamond lappato abrasive in ceramics manufacturing is the Silicon Carbide Lappato Abrasive, renowned for its distinctive surface finishing capabilities. When it comes to abrasive selection for ceramic applications, Silicon Carbide stands out for its effectiveness in achieving superior surface enhancement. This abrasive type plays a significant role in modern finishing technology, offering precise polishing techniques that cater to the meticulous requirements of the industry. Below is a table highlighting key features of Silicon Carbide Lappato Abrasive:

| Feature | Description | Benefit |

|---|---|---|

| Surface Finish | Smooth and glossy finish | Enhanced aesthetics |

| Durability | Long-lasting performance | Cost-effective |

| Versatility | Suitable for various ceramics | Increased flexibility |

| Efficiency | Quick material removal | Time-saving |

| Consistency | Uniform results | Quality assurance |

Demonstrating exceptional abrasion capabilities, Alumina Lappato Abrasive has become a prominent choice in the realm of ceramics finishing techniques.

Alumina Lappato Abrasive is well-suited for various applications due to its versatility and effectiveness. When employing this abrasive, mastering proper grinding techniques and adhering to maintenance tips are crucial for optimal results.

Whether used in tile manufacturing, architectural ceramics, or artistic creations, Alumina Lappato Abrasive delivers exceptional outcomes across a wide array of ceramic finishing tasks.

Mastering the art of ceramic finishing requires an understanding of what constitutes a high-quality lappato abrasive. When evaluating lappato abrasives for quality, several key features must be considered.

Firstly, the abrasive should meet strict quality standards to ensure consistent results. It should be capable of delivering a surface smoothness that is free of imperfections like scratches. A high-quality lappato abrasive should also exhibit long-lasting performance, allowing for the completion of a large number of tiles without compromising its effectiveness.

Additionally, ease of cleaning maintenance is essential for efficient operations. The abrasive material should facilitate easy cleaning and maintenance of the finished surface without the need for specialized products or excessive upkeep. Materials such as diamond abrasives, silicon carbide abrasives, and alumina abrasives are commonly recognized as high-quality lappato abrasives due to their durability and ability to produce superior finishes on ceramic tiles.

Related Article: Different Types of Abrasive Materials Used in Grinding Wheels

Selecting the appropriate lappato abrasive tools for ceramic tile production involves careful consideration of key factors such as the type of abrasive material used and the specific application requirements. When choosing lappato abrasive tools, the following factors should be taken into account:

It is essential to consider the tile specifications, including size, shape, and desired level of abrasiveness when selecting lappato abrasive tools. Additionally, understanding the production process and its intricacies can help in making informed decisions. Expert consultation with specialists or experienced ceramic tile manufacturers can provide valuable insights and guidance to ensure the most suitable lappato abrasive tools are chosen for the job.

Related Article: Varieties of Ceramic Tile Polishing Abrasives and Choosing Guide

Before deciding on customized Lappato abrasive tools for ceramic tile production, it is crucial to evaluate the unique requirements and specifications of the manufacturing process. Customized options offer tailored solutions that can enhance quality assurance by addressing specific needs efficiently.

When considering abrasive tools, cost-effective solutions coupled with a high durability factor are essential for long-term performance and cost savings. Understanding the surface preparation and application techniques required for the customized abrasive tools is vital to ensure optimal results in ceramic tile production.

Moreover, it is necessary to assess the maintenance requirements and performance standards of the customized Lappato abrasive to guarantee consistent quality output. Manufacturers should also seek technical support from suppliers to streamline the integration of customized abrasive tools into their production processes.

Ultimately, customer satisfaction hinges on the reliability and effectiveness of the chosen abrasive tools. By carefully considering these factors before opting for customized Lappato abrasive, manufacturers can achieve enhanced productivity and superior quality in their ceramic tile production.

Related Article: How a Polishing Abrasives Manufacturer Elevates Your Finishing

In conclusion, mastering the use of lappato abrasive for ceramics is essential for achieving a high-quality finish. Despite its benefits and various types available, selecting the right lappato abrasive tools can be a challenging task.

However, considering the considerations before opting for customized lappato abrasive can help in making the right choice. Remember, in the world of ceramics, the true beauty lies in the meticulous attention to detail and the precision of the finishing process.

GINGONG in China offers high-quality diamond polishing and edge grinding tools alongside ceramic machinery accessories. Our integrated solutions cater to individual needs, ensuring optimal performance and efficiency. We lead the industry in ceramics polishing, emphasizing effectiveness, cost control, and environmental sustainability. With "Sanmo" machines and meticulous attention to detail, GINGONG delivers top-notch abrasive products, setting the standard for excellence.

Contact us for a free quote of your ideal Lappato Abrasive for Ceramics!