When it comes to achieving a flawless finish on surfaces, the use of glaze polishing abrasives is paramount in various industries. Understanding the intricacies of these abrasives, their composition, and the methods employed in their application is essential for professionals seeking impeccable results.

Delving into the realm of glaze polishing abrasives not only unveils the nuances of the polishing process but also sheds light on the diverse range of abrasives available in the market. As we explore the realm of glaze polishing abrasives, we uncover a world where precision and technique merge to create surfaces of unparalleled smoothness and shine.

Glaze polishing abrasives, commonly referred to as diamond elastic grinding blocks or lapato abrasives, are essential tools used for polishing the surfaces of ceramic tiles, stone-like porcelain tiles, and glaze tiles with precision and efficiency. These abrasives play a crucial role in surface preparation, ensuring that the surfaces are smooth and flawless before the final finishing touches are applied. Whether it's for ceramic tiles or stone-like porcelain, these abrasives are versatile and can be used for various surface finishing techniques.

The glaze polishing techniques employed with these abrasives are designed to achieve exceptional results, providing a high level of clarity without leaving any scratches behind. To meet the demands of professionals in the industry, these abrasives must exhibit good sharpness, strong abrasion strength, long working life, and pass stringent product tests for service lifetime. This ensures that the ceramic tiles and stone-like porcelain surfaces receive the meticulous care and attention they require for a pristine finish.

In the context of surface preparation for ceramic tiles, stone-like porcelain tiles, and glaze tiles, the abrasives used in polishing typically consist of materials such as silica, corundums, ceria, and zirconia. These abrasive particles play a crucial role in determining the efficiency and effectiveness of the polishing process.

Here are some key factors to consider regarding the abrasives used in polishing:

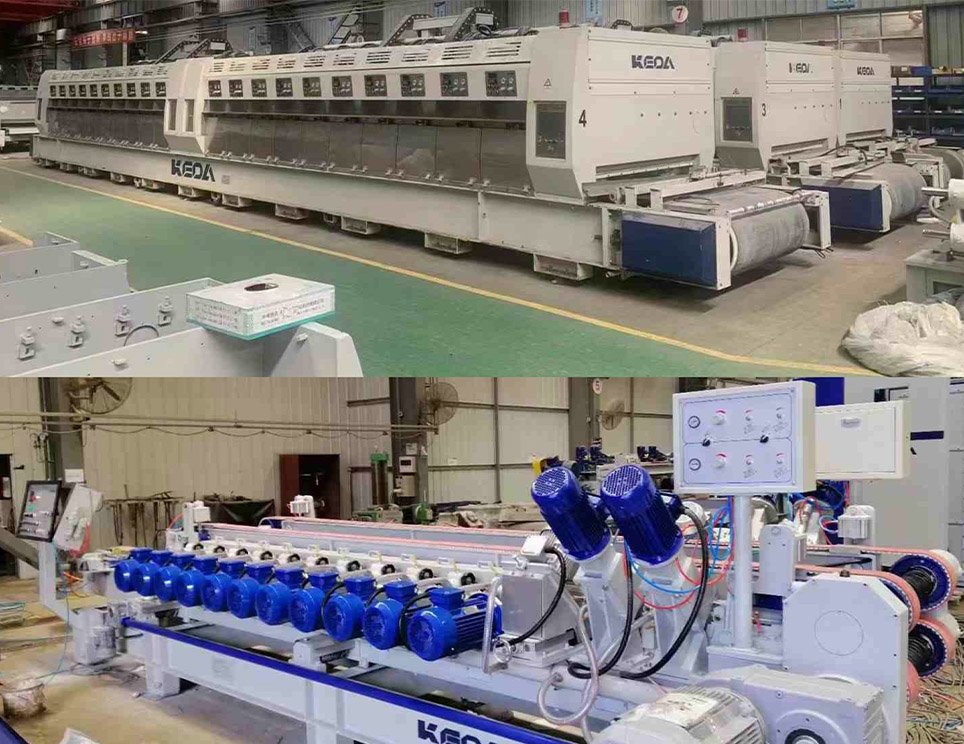

The polishing process is a meticulous technique employed to refine and enhance the surface of ceramic tiles, stone-like porcelain tiles, and glaze tiles. Polishing techniques vary based on the material being polished, with common methods including mechanical polishing using rotating pads or belts and chemical polishing using specific compounds.

The benefits of polishing include achieving a smooth, glossy finish that enhances the aesthetic appeal of the tiles, making them more resistant to stains and easier to clean. Polishing tools such as rotary polishers, polishing pads, and abrasive discs are essential for achieving the desired level of smoothness and shine. Polishing compounds, which can be in the form of liquids or pastes, help in removing surface imperfections and enhancing the overall appearance of the tiles.

Some polishing tips to keep in mind are to start with a lower grit polishing compound and gradually increase the grit size for a smoother finish, always work in small sections, and regularly clean the polishing tools to ensure optimal performance.

Polishing and glazing are distinct processes in surface treatment that serve different purposes and result in contrasting finishes for various materials. Understanding the disparity between the two techniques is crucial for achieving the desired results.

Here are the key differences:

When considering types of glaze polishing abrasives, two common options are Silicon Carbide and Diamond Abrasives. These abrasives are known for their effectiveness in achieving high gloss finishes on various glazed porcelain and ceramic tiles.

Understanding the specific characteristics and applications of each abrasive type is crucial for achieving the desired polishing results in tile manufacturing processes.

In the realm of abrasive tools for glaze polishing, silicon carbide stands out as a reliable choice due to its effectiveness in grinding and smoothing hard materials such as glaze tiles.

When considering silicon carbide for glaze polishing, here are some key points to keep in mind:

Diamond abrasives, known for their exceptional precision, are indispensable tools for achieving a superior polished finish on glaze tiles. These diamond tools come in various forms such as grinding wheels, polishing pads, and diamond-coated discs, making them highly versatile for surface finishing.

Their effectiveness in removing scratches and restoring the shine of glaze tiles is unmatched. Diamond abrasives are a go-to choice for professionals who prioritize quality and efficiency in their work. When working with abrasive materials, the use of diamond abrasives ensures consistent results and a high level of control over the polishing process.

Whether in a workshop or on-site, the reliability of diamond abrasives makes them a preferred option for achieving top-notch glaze tile finishes.

How can the selection of appropriate glaze polishing abrasives enhance the efficiency of the polishing process? When using glaze polishing abrasives, the right choice can significantly impact the final surface finish. Whether working on ceramic tiles, marble countertops, or in the automotive industry, achieving the desired gloss enhancement relies on the correct application of abrasives. Here are key points to consider:

When considering the specification of glaze polishing abrasives, it is essential to focus on three key points: grit, shape, and application.

The grit size determines the level of abrasiveness, while the shape of the abrasive impacts the polishing pattern.

Understanding the application requirements is crucial for selecting the most suitable abrasive for achieving desired glaze polishing results.

To achieve optimal results in glaze polishing, the specification of the abrasive grit used plays a crucial role in determining the final surface finish. When considering the grit for glaze polishing abrasives, several key factors must be taken into account:

Careful consideration of these factors will lead to improved glaze polishing results and enhanced overall quality.

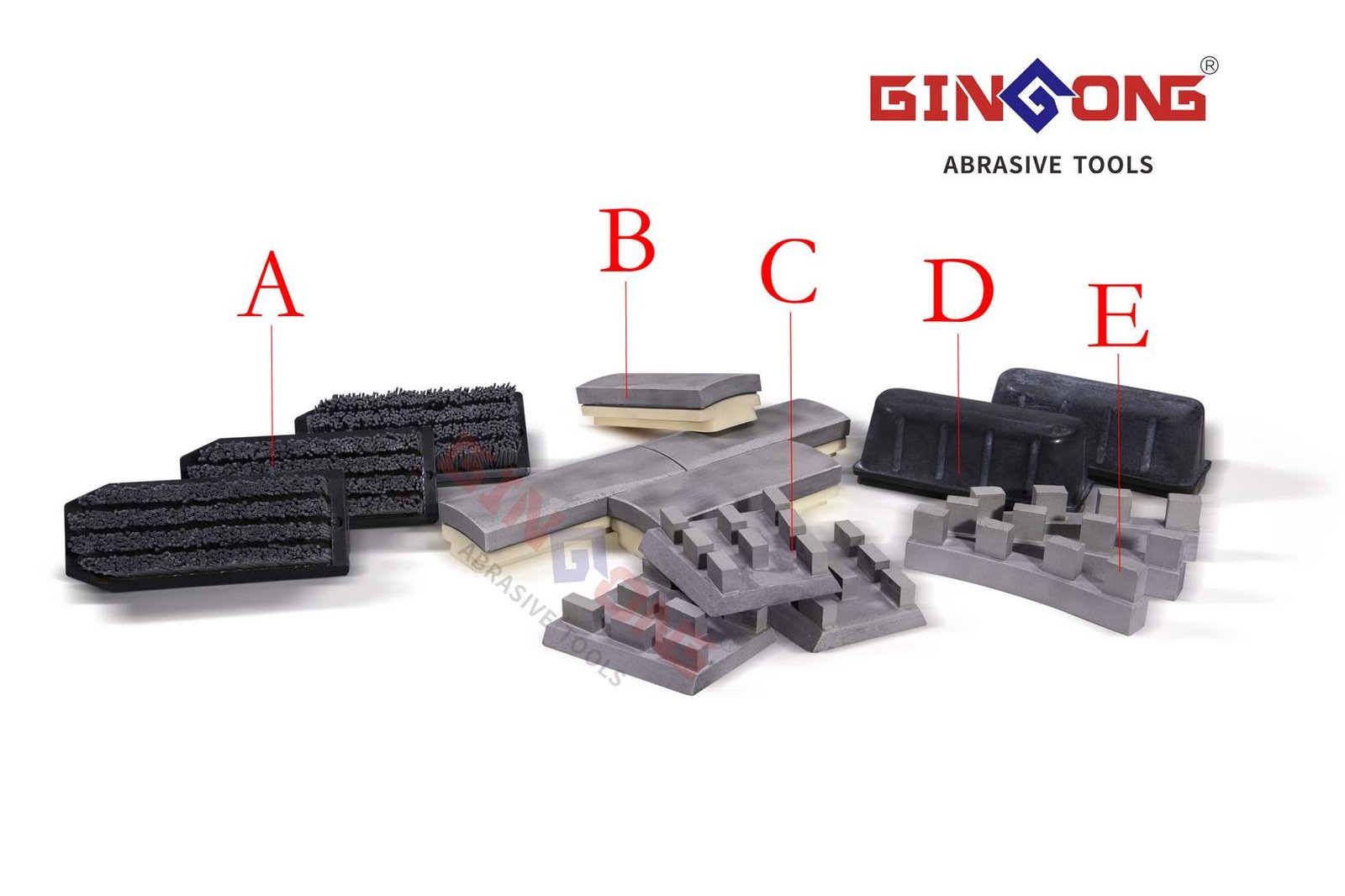

The shape of the abrasive used in glaze polishing is a critical aspect that significantly influences the precision and effectiveness of the polishing process. Abrasives come in various shapes such as discs, wheels, cones, and points, each tailored for specific applications.

Disc-shaped abrasives are commonly used for achieving a smooth surface finish, while wheel-shaped abrasives excel in material removal. Cones and points are ideal for edge rounding and contour shaping, providing intricate detailing and precision in the polishing process.

Choosing the right shape of abrasive is essential for achieving desired results, whether it be for surface finish perfection or gloss enhancement. Understanding how each shape contributes to the overall polishing process is key to mastering the art of glaze polishing.

In glaze polishing, the specification of the abrasive is tailored to the application, considering various factors such as the material and size of the tiles being polished. When selecting the abrasive for glaze polishing, it is crucial to focus on:

These considerations will not only enhance the polishing process but also prolong the life of the tiles.

Surface compatibility is crucial when using glaze polishing abrasives. Different surfaces may require specific application methods, abrasive grits, and polishing techniques to achieve the desired finish quality. Understanding surface nuances ensures optimal results.

When working with glaze polishing abrasives, safety precautions are paramount. Proper ventilation ensures a clear workspace. Eye and skin protection shield against potential harm. Regular equipment maintenance guarantees optimal performance. Lastly, proper disposal methods promote a clean environment.

The polishing time can vary based on the complexity of the surface and technique used. Efficiency improves with experience and proper equipment. Common mistakes include rushing the process, which can compromise quality. It's essential to balance speed with quality for optimal results.

Material compatibility is crucial when using glaze polishing abrasives on delicate surfaces. Understanding surface sensitivity, appropriate polishing techniques, abrasive grit, and finishing options is essential. Always test on a small area first to ensure compatibility and desired results.

For those seeking environmentally conscious choices in glaze polishing abrasives, several options exist. Biodegradable options, sustainable alternatives, and eco-friendly solutions are available, providing green polishing methods that minimize environmental impact while maintaining effective results.

In conclusion, glaze polishing abrasives play a crucial role in achieving a smooth and glossy finish on various surfaces.

While some may argue that the process of polishing can be time-consuming, the end result of a perfectly polished surface that sparkles like a mirror is well worth the effort.

With the right abrasives and techniques, glaze polishing can transform an ordinary surface into a work of art.