In the world of manufacturing, the importance of selecting the appropriate abrasive grinding wheel material cannot be overstated. This choice directly shapes the effectiveness, efficiency, and longevity of the tool, impacting the overall quality of the finished product.

With an array of materials available, each boasting unique properties and benefits, it becomes crucial to comprehend the subtleties and nuances that differentiate one from another. This understanding can not only enhance the performance and productivity of manufacturers but also drive innovation in this crucial area.

However, the question persists: what exactly should manufacturers be looking for when it comes to abrasive grinding wheel materials, and how do these materials impact the tool's performance? Let's embark on an exploration of this pertinent topic.

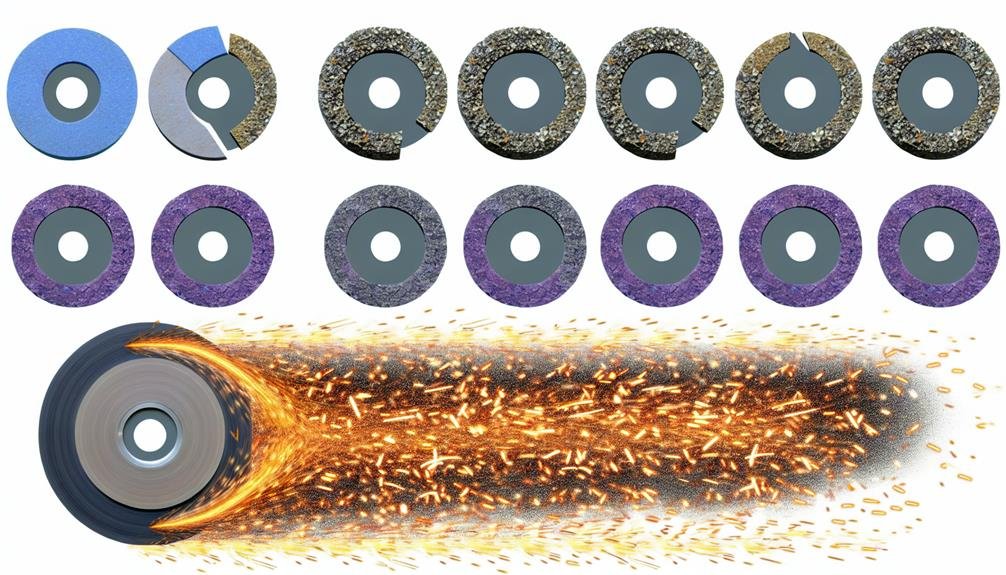

In the realm of abrasive grinding wheels, various types exist, each with unique attributes and applications. These include:

A comprehensive understanding of these types and their specific uses can significantly enhance manufacturing processes and outcomes.

Straight wheel abrasive grinding wheels, commonly used in tools such as chisels, possess the versatility to perform various types of grinding tasks. Their design allows for optimal material removal, contributing to a superior surface finish. Precision grinding is a key feature of these wheels, enabling users to achieve the desired result with minimal wheel wear. However, they do generate heat, which must be managed to maintain the integrity of the tool and the workpiece.

Shifting focus to the cylinder or wheel ring, this type of abrasive grinding wheel is predominantly used in the creation of flat surfaces, with the grinding process being performed by the end face of the wheel. The wheel geometry of this type is designed to facilitate precision grinding operations.

The material composition of the cylinder wheel ring is thoughtfully selected to ensure optimal heat generation and wear resistance, allowing for a sustainable and efficient grinding process. This extends the longevity of the wheel, ensuring consistent performance over an extended period. Additionally, the wheel ring ensures an exceptional surface finish, further bolstering the quality of the end product. These characteristics make the cylinder or wheel ring an invaluable asset in abrasive grinding operations.

Pivoting to the tapered wheel, this type of abrasive grinding wheel is primarily utilized for the precise grinding of thread and gear teeth. It offers a range of benefits and applications, including providing the precision required in various manufacturing processes.

Mastering these aspects gives you control over the product's performance and quality.

Moving from the precision-oriented tapered wheel, we now turn our attention to another key type of abrasive grinding wheel, the straight cup, renowned for its utility in cutting tools and cutter grinders.

The straight cup wheel employs specific grinding techniques, maximizing material compatibility for optimal results. Performance evaluation reveals its effectiveness in creating precise angles and shapes, meeting the exacting demands of various industry applications.

However, it's crucial to remember that, like all grinding wheels, the straight cup requires ongoing wheel maintenance to sustain its performance and longevity. Therefore, manufacturers need to ensure they manage the wear and tear effectively to maintain its function.

Have you considered the dish cup, another type of abrasive grinding wheel, primarily used for cutter grinders and jig grinders? It offers several advantages and applications, with design considerations and maintenance tips that can help prolong its life and efficiency.

When choosing a dish cup, material selection is critical. Here are key points to consider:

While the dish cup is particularly beneficial for cutter and jig grinders, another abrasive grinding wheel that is worth considering is the diamond wheel, which is primarily utilized in the perfection of industrial diamonds.

Diamond wheel benefits are multiple. They offer a high degree of hardness and thermal conductivity, providing superior grinding performance. The diamond wheel manufacturing process involves embedding diamond particles into the wheel's surface, enhancing its abrasive capabilities. In terms of diamond wheel applications, they are extensively used in industries like electronics, ceramics, and glass due to their precision and durability.

However, diamond wheel maintenance is crucial to ensure optimal performance and longevity. Regular cleaning and dressing of the wheel can prevent glazing and loading, thus enhancing its efficiency.

In the realm of abrasive grinding wheels, cut off wheels play an integral role, specifically in the construction of reinforcement bars and operations necessitating swift removal and trimming. The efficacy of these wheels is heavily influenced by their abrasive composition, which contributes significantly to their cutting efficiency.

Furthermore, it's critical to consider aspects such as:

These factors ensure that manufacturers maintain control over their production process, thereby optimizing operational efficiency.

Composed of grain, bond, and pore, the grinding wheel's performance is significantly determined by these three crucial elements. The grain composition is the primary determinant of the wheel's cutting ability. Different materials require specific grain types for optimum performance, and understanding these requirements enables manufacturers to control the grinding wheel's effectiveness.

The second element, bond types, plays a vital role in the wheel's structure. Various bond types are available, each suited to different grinding conditions. The bond holds the grains together and influences the wheel's hardness and wear resistance, directly affecting the wheel material properties.

Lastly, the pore structure refers to the spaces between the grains and bonds. The pores provide a vital function in chip removal and coolant retention during the grinding process. Their size and distribution influence the wheel's cutting ability and lifespan, further impacting the grinding wheel's performance.

In essence, these three elements—grain, bond, and pore—form an interdependent system. Each component's characteristics significantly impact the wheel's overall performance, underscoring the need for manufacturers to understand and control these elements to achieve the desired grinding results.

As a commonly utilized abrasive material, aluminum oxide holds a significant role in the manufacturing of grinding wheels due to its excellent hardness and durability. It is crucial for manufacturers to understand the oxide production process, oxide safety measures, aluminum oxide sourcing, and oxide disposal methods.

Current market trends indicate a growing demand for aluminum oxide. Key points to consider include:

Understanding these aspects allows manufacturers to optimize their operations and product quality.

Moving from aluminum oxide, another widely used abrasive material in the manufacturing of grinding wheels is Silicon Carbide, known for its superior hardness and thermal conductivity. This ensures Silicon durability, a vital attribute for any abrasive material exposed to high stress environments.

Silicon Carbide production is a meticulous process, ensuring its unique properties are maintained. It has a reputation for safety, thanks to its chemical inertness and high melting point. Carbide applications are diverse, from cutting tools to automotive parts. Lastly, Silicon recycling initiatives offer an eco-friendly aspect to its usage.

| Attribute | Silicon Carbide | Aluminum Oxide |

|---|---|---|

| Durability | High | Moderate |

| Applications | Diverse | Limited |

| Safety | High | Moderate |

| Production | Meticulous | Simple |

| Recycling | Possible | Limited |

Understanding these factors gives manufacturers control over their product quality and sustainability initiatives.

Next in the lineup of abrasive materials for grinding wheel manufacturing is Cubic Boron Nitride, renowned for its second-highest hardness level after diamond. This material is vital in industries that require precision and efficiency, due to Boron Nitride's durability and heat resistance properties.

Key aspects to consider about Cubic Boron Nitride include:

Understanding Cubic Boron Nitride will provide manufacturers with greater control over their grinding wheel performance and lifespan.

While Cubic Boron Nitride offers robust and heat-resistant qualities, diamond, as an abrasive material, stands at the pinnacle of hardness and thermal conductivity, making it a prime choice for grinding wheel manufacturing.

The diamond's heat resistance lends itself to the durability of the grinding wheel, enabling it to withstand high-temperature operations. This diamond durability, in turn, ensures long-term, cost-efficient usage.

Furthermore, the diamond versatility allows for the grinding of a broad array of materials, from the toughest steel to delicate ceramics. Diamond wheel maintenance is relatively low, adding to the overall grinding efficiency of diamond-based wheels.

Hence, incorporating diamond into the manufacturing process can yield superior grinding products offering enhanced performance and longevity.

Have you considered Ceramic Aluminium Oxide as an abrasive material for grinding wheel manufacturing? This compound combines the ceramic durability with the impressive oxide properties to result in an abrasive that is tough, durable, and ideal for grinding applications.

Ceramic Aluminium Oxide offers superior longevity due to the strength of the ceramic component in the compound.

The oxide properties assist in enhancing the overall performance of the grinding wheel.

The safety measures are enhanced with this material due to its heat resistance.

The manufacturing process is streamlined, making it a cost-effective choice for industrial applications.

To ensure optimal performance and safety in your manufacturing processes, consider the benefits of Ceramic Aluminium Oxide for your grinding wheels.

Shifting our focus from Ceramic Aluminium Oxide, another reliable abrasive material that merits consideration is Zirconia Alumina, known for its exceptional grinding performance.

Zirconia Alumina's durability and properties make it a standout choice for manufacturers seeking control over their grinding processes. Zirconia applications are vast, due to its inherent toughness and ability to withstand aggressive grinding procedures. This, coupled with the sourcing of Alumina, a naturally abundant material, makes Zirconia Alumina a cost-effective solution.

The benefits of Zirconia Alumina are manifold, including its high-temperature resistance and longevity in grinding and cutting operations. As a manufacturer, understanding these attributes and effectively integrating Zirconia Alumina into your processes can foster quality and efficiency in your production line.

In the realm of abrasive grinding wheel materials, understanding the role of grains and grain blends becomes crucial. These components, including Ceramic Alumina, Zirconia Alumina, and blends of Zirconia Alumina with Ceramic Alumina, as well as White Aluminum Oxide and Aluminum Oxide, offer unique properties to the grinding process.

In the following discussion, we will examine these materials in detail, exploring their individual characteristics and their impact on grinding wheel performance.

Ceramic Alumina, known for its grains and grain blends, offers self-sharpening and micro-fracturing crystals, providing a significantly longer operating life under moderate to high pressure. This property enhances grinding wheel efficiency and is a key ceramic alumina benefit. The grains grind at lower temperatures, generating less friction, thus improving the overall ceramic alumina performance in grinding wheel applications.

These ceramic alumina properties offer significant benefits, allowing for superior control over grinding processes.

Turning our attention to Zirconia Alumina, this material, known for its grains and grain blends, demonstrates exceptional durability and cutting speed, particularly on metal workpieces such as steel and stainless steel. The Zirconia alumina benefits stem from its abrasive properties and inherent toughness, which enable high grinding efficiency. The self-sharpening grains maintain their cutting edge, even under high pressures and extreme temperatures, contributing to consistent material removal, thereby enhancing the manufacturing applications.

Crucial in material selection, Zirconia Alumina offers a balance between cost and performance, creating an attractive proposition for manufacturers. It delivers a fast cut and a long life, making it a preferred choice for grinding wheels in various industrial settings.

While Zirconia Alumina's inherent toughness and high grinding efficiency are highly valued, an enhanced performance can be achieved when this abrasive is blended with Ceramic Alumina, resulting in faster cutting with less effort. The blending techniques used to combine these materials result in a unique set of material characteristics that offer numerous performance advantages.

The Ceramic blend benefits include:

These benefits make this blend an attractive choice for manufacturers seeking control over their grinding operations while optimizing performance and productivity.

In the realm of abrasive grinding wheel materials, White Aluminum Oxide - both in pure form and in grain blends - stands out due to its impressively fast cut-rate and remarkable lifespan. This material boasts an exceptional grinding efficiency, leading to a superior surface finish. Its high friability ensures fresh, sharp grains are exposed at all times, contributing to its impressive cutting speed.

White Aluminum Oxide is also admired for its heat resistance, allowing it to perform well in high-stress grinding situations without compromising wheel longevity. Moreover, its compatibility with harder-grade steel and stainless steel makes it a versatile choice for manufacturers. The combined benefits of White Aluminum Oxide make it a preferred choice in the production of abrasive grinding wheels.

Diving into the realm of Aluminum Oxide, both as pure grains and grain blends, this material is noted for its remarkable durability and sharp, fast initial cut, making it an ideal choice for grinding steel, iron, and other metals.

Despite its many benefits, Aluminum Oxide does have limitations, including a tendency to dull over time and a lower cut-rate compared to other grains.

Shifting the focus to Silicon Carbide, both in its pure grain form and grain blends, it is worth noting that this material is distinguished by its extreme hardness, sharp and fast cutting abilities, albeit being friable and less robust than other grains. Silicon carbide properties make it a key player in various applications, particularly in abrasive and refractory industries. Its hardness lends to its advantages in cutting and grinding applications where precision is paramount.

Yet, its friability and lesser toughness - limitations not to be overlooked - require careful handling to prevent damage. Despite these, the pursuit of silicon carbide innovations continues unabated, with manufacturers tirelessly working to enhance its toughness without compromising the cutting efficacy, marking a promising future for this versatile abrasive grain.

Harnessing the strengths of both silicon carbide and aluminum oxide, a blended grain grinding wheel offers superior grinding abilities, particularly for aluminum and other soft alloy materials. This combination enhances both grinding performance and material compatibility, making it an excellent choice for manufacturers.

Key benefits include:

Thus, this blend holds immense potential for improving efficiency and quality in manufacturing.

Understanding the types of bonds in abrasive grinding wheels is crucial for manufacturers in order to select the right wheel for specific applications. Five main types of bonds are commonly employed; Vitrified or Ceramic Bonds, Resinoid or Organic Bonds, Rubber Bonds, Silicate Bonds, and Magnesite Bonds.

Each bond type has unique characteristics that affect the performance, durability, and suitability of the grinding wheel in different operating conditions.

In the realm of abrasive grinding wheel materials, the vitrified or ceramic bond, denoted by the symbol 'V', employs ceramics like feldspar and clay, which are fired to bind abrasive grains together. This bond offers distinct advantages over resinoid bonds, in terms of both performance and versatility.

Key advantages of vitrified bonds include:

These ceramic bond properties make vitrified bonds ideal for precision grinding applications.

Switching our focus to resinoid or organic bonds, denoted by the symbol 'B', these employ hardened or thermoset bakelite, offering elasticity and high tensile strength that makes them suitable for use under high operation speeds. Resinoid bond advantages include high-speed operation capabilities and suitability for thin grinding wheels like cutting wheels.

In terms of resinoid bond applications, they are primarily utilized in cutting and depressed centered wheels. However, resinoid bond limitations must be considered. These bonds are easily affected by heat and oil, necessitating careful control of the grinding fluid.

Lastly, considering resinoid bond properties, they are elastic, high tensile and sensitive to environmental factors. Thus, when choosing a bond, these resinoid bond considerations should be taken into account.

Diving into the realm of Rubber (R) Bonds, denoted by the symbol 'R', this method involves products manufactured by hardening or thermosetting natural or synthetic rubber tempered with grains. The rubber bonding process offers flexibility and good frictional grip, making it ideal for precision applications. However, it also has its limitations; rubber bonds are easily affected by heat and oil, necessitating careful maintenance.

Moving on to Silicate (S) Bonds, these are known for releasing abrasive grains readily, which results in a relatively mild and cool cutting action, making them ideal for operations requiring minimal heat and for sharpening edged tools. The bond properties of Silicate bonds, including bond strength and abrasive release, contribute significantly to their cooling effect.

The table below highlights the key features of Silicate bonding:

| Feature | Description | Benefit |

|---|---|---|

| Bond Strength | Moderate | Ensures durability |

| Abrasive Release | High | Promotes a cool cutting action |

| Cooling Effect | Significant | Minimizes heat during operation |

While the Silicate bonds provide a cool cutting action, the Magnesite (O) Bond, denoted by the letter 'O', offers a unique set of features that set it apart in the abrasive grinding wheel industry. The bond characteristics of Magnesite include cool cutting even without a coolant, making it a favorite amongst disc grinders.

These features make Magnesite an essential bond type in the abrasive grinding wheel market.

In the realm of abrasive grinding wheel materials, metal bonds, although used less frequently than vitrified and organic bonds, play a critical role especially when grinding under harsh conditions. Despite their less frequent usage, metal bonds have several advantages. Their longevity benefits make them particularly suitable for applications such as glass grinding, abrasive wheel shaping and concrete or stone sawing, despite the high heat generation. Furthermore, their conductive properties have facilitated their use in electrolytic grinding.

| Metal Bond Advantages | Key Applications |

|---|---|

| Longevity benefits | Glass grinding |

| High heat generation | Abrasive wheel shaping |

| Conductive properties | Electrolytic grinding |

| Resilience in harsh conditions | Concrete or stone sawing |

| Slow material removal | Diamond abrasive use |

The process of selecting the right grinding wheel necessitates careful consideration of two primary factors: the diameter and thickness of the wheel, both of which significantly influence the wheel's performance and usability.

The diameter of the wheel is paramount for ensuring safety measures and achieving productivity benefits. It should align with the tool's RPM to safeguard the operator and the equipment. Moreover, the diameter affects the longevity of the wheel, reducing the frequency of replacements and thus enhancing productivity. Workspace constraints also influence the choice of diameter, as smaller wheels may be necessary for confined spaces.

Thickness considerations are equally crucial. A quarter-inch thickness typically offers a balance of precision, wheel life, and cut-rate during grinding. Meanwhile, 1/8-inch thickness wheels allow for both 90-degree cuts and shallow-angled grinding without the need to change the abrasive.

In summary, when selecting a grinding wheel, consider:

Environmental conditions significantly impact the performance of abrasive grinding wheel materials. Material selection, temperature impacts, humidity effects, and maintenance practices are key performance variables that manufacturers should consider for optimal functionality and longevity of grinding wheels.

Manufacturing and using abrasive grinding wheels necessitates stringent safety measures including regular wheel maintenance, use of protective equipment, comprehensive manufacturer training, adherence to handling procedures, and robust fire prevention strategies to mitigate potential hazards.

The production process of abrasive grinding wheels has evolved significantly due to historical developments, technological advancements, and improved material sourcing strategies, leading to more efficient cost analysis and enhanced quality control measures.

Future innovations in the abrasive grinding wheel industry may include nanotechnology applications, smart abrasives, and hybrid wheel development. The impact of automation and Industry 4.0 will also likely drive significant advancements in the sector.

Yes, the industry is evolving towards sustainable practices including green manufacturing processes, recycling practices, and sustainable sourcing. Eco-friendly binders and biodegradable abrasives are increasingly utilized in abrasive grinding wheel production.

In conclusion, understanding the diverse types of abrasive grinding wheel materials is paramount for manufacturers.

The three key elements - abrasive material, grains, and bonds - play significant roles in determining the performance and longevity of the wheel.

The selection of the right grinding wheel, therefore, demands an in-depth knowledge of these elements.

This understanding fosters the production of high-quality grinding wheels, thereby enhancing efficiency and productivity in various manufacturing applications.

In conclusion, understanding the dynamics of abrasive grinding wheels, including the different types, bonds, and operations, is essential in maximizing their potential and ensuring optimal performance.

This knowledge provides the key to unlocking the full spectrum of the wheel's capabilities, from the grit and grade to the structure and bond type, facilitating the creation of precise and high-quality workpieces.

GINGONG in China offers high-quality diamond polishing and edge grinding tools alongside ceramic machinery accessories. Our integrated solutions cater to individual needs, ensuring optimal performance and efficiency. We lead the industry in ceramics polishing, emphasizing effectiveness, cost control, and environmental sustainability. With "Sanmo" machines and meticulous attention to detail, GINGONG delivers top-notch abrasive products, setting the standard for excellence.

Contact us for a free quote of your ideal abrasive grinding wheel!