In the intricate world of ceramic surface treatment, precision is paramount.

Diamond Lappato abrasives stand at the forefront of this realm, offering a level of exactitude and finesse that is unparalleled. These specialized tools are designed to elevate the quality of ceramic surfaces to a degree that exceeds conventional methods. Their unique properties and cutting-edge technology set them apart, promising a new standard in surface treatment.

As we delve into the intricacies of Diamond Lappato abrasives and their applications, a fascinating world of precision and innovation awaits.

A Diamond Lappato Abrasive for ceramics is a specialized tool used for polishing ceramic tile surfaces to achieve a lappato finish. These abrasives are essential for providing precision in the treatment of ceramic surfaces, ensuring a high-quality and smooth finish.

Ficket polishing tools are commonly utilized in the stone processing industry for their effectiveness in achieving the desired surface texture.

Utilizing precision-engineered diamond particles embedded in a bonding material, the Diamond Lappato Abrasive for ceramics is renowned for its exceptional hardness and durability in grinding and polishing ceramic surfaces.

This abrasive tool offers control and reliability in achieving desired ceramic surface treatments, making it a preferred choice for professionals seeking impeccable results in ceramic surface finishing.

The Diamond Lappato Abrasive for ceramics plays a crucial role in the treatment and polishing of ceramic tile surfaces, ensuring precision and quality in achieving desired textures and finishes.

Ceramic polishing techniques utilize this tool for grinding and polishing surfaces to specific textures and finishes, making it a vital component in tile finishing methods.

These precision tools offer a range of surface treatment options, allowing for customization and control over the final look of the ceramic tiles.

Precision and sophistication converge in the realm of ceramic surface treatment through the innovative application of Diamond Lappato Abrasives. The Lappato finish is a unique surface texture achieved through specific polishing techniques using abrasive tools.

Key aspects of this finish include:

This technique combines matte and glossy elements to produce a visually appealing tile surface. By carefully manipulating the material with diamond abrasives, the Lappato finish showcases a controlled balance of shine and texture, offering a sophisticated aesthetic for various ceramic applications.

In the realm of ceramic surface treatment, the application of Ficket Polishing Tools for Stone Processing introduces a specialized abrasive known as the Diamond Lappato abrasive, offering enhanced efficiency and glossiness for ceramic surfaces. These tools are integral to stone polishing techniques, surface treatment methods, and ceramic finishing processes. The careful selection of polishing tools is crucial for achieving the desired surface quality and finish in stone processing operations. Ficket Polishing Tools excel in enhancing glossiness, improving productivity, and ensuring reliable quality in stone surface treatments. Their role in abrasive tool applications is paramount, contributing to energy efficiency and superior outcomes in the stone processing industry.

| Advantages | Description |

|---|---|

| Energy Efficiency | Sharpness reduces stress on grinding heads, extending equipment lifespan and saving energy. |

| Improved Productivity | Superior sharpness enhances conveyor belt speed, increasing production efficiency. |

| Enhanced Glossiness | Elevates glossiness of stone surfaces, exceeding standard levels for an exquisite finish. |

| Reliable Quality | Manufactured with precision, they maintain high quality standards, offering cost-efficient solutions. |

Diamond Lappato abrasives are characterized by their hardness, toughness, and friability, which contribute to their effectiveness in ceramic surface treatment.

Additionally, factors such as grit size and particle shape play a crucial role in determining the abrasives' precision and performance.

Moreover, abrasive strength and cutting efficiency are key properties that impact the overall quality of the surface treatment process.

Properties such as hardness, toughness, and friability play a critical role in determining the effectiveness and performance of diamond lappato abrasives in various surface treatment applications.

These properties are essential for maintaining control during surface treatments. By understanding the material characteristics, tool maintenance, and grinding techniques, operators can optimize the use of diamond lappato abrasives for precise and effective ceramic surface treatments.

Consideration of grit size and particle shape is pivotal when evaluating the performance of diamond lappato abrasives in surface treatment applications. Particle selection based on these factors directly impacts surface precision, abrasive efficiency, material removal rates, and the effectiveness of finishing techniques.

The grit size determines the aggressiveness of the abrasive action, with coarser grits excelling in rapid material removal and finer grits yielding smoother finishes. Moreover, the particle shape influences the cutting mechanism, where angular particles exhibit more aggressive cutting capabilities compared to rounded particles, which are better suited for achieving fine finishes.

Particle selection based on specific abrasive properties plays a crucial role in determining the cutting efficiency and material removal rates of diamond lappato abrasives in surface treatment applications. When analyzing abrasive strength for these abrasives, the following points are essential:

These properties are integral to optimizing surface treatment techniques, enhancing precision polishing methods, and achieving superior material removal rates while maintaining control over the cutting process. By assessing abrasive strength and cutting efficiency, operators can tailor their processes for maximum productivity and quality outcomes.

Diamond Lappato abrasives operate by utilizing a combination of material removal, diamond resin, and water lubrication to achieve a smooth and glossy surface finish on ceramic tiles. The polishing technique involves gradual material removal, aided by the diamond resin for fine polishing, ensuring a glossy finish and uniformity assurance. Water lubrication plays a crucial role, controlling the temperature to prevent overheating during the process and maintaining optimal working conditions. The lappato abrasive's semi-polishing action contributes to the desired lappato texture, combining the benefits of full polishing and semi-polishing for a unique finish. This process allows for precise surface precision in ceramic treatment, enhancing the overall quality of the tiles. By understanding the intricate interplay between these elements, professionals can achieve exceptional results in ceramic surface treatment.

| Keywords | Description | Benefits |

|---|---|---|

| Surface Precision | Achieving accurate and smooth ceramic treatment | Enhanced quality |

| Polishing Technique | Gradual material removal with diamond resin | Fine polishing |

| Glossy Finish | Water lubrication for a glossy and uniform appearance | Enhanced aesthetics |

| Water Lubrication | Control of temperature and prevention of overheating | Optimal working conditions |

| Lappato Texture | Achieving a unique lappato finish | Combines polishing types |

The versatile utilization of lappato abrasives in various industries underscores their significant impact on enhancing surface quality and finish. When it comes to the applications of Diamond Lappato Abrasives, their benefits extend across various areas:

Precision polishing with Diamond Lappato Abrasives not only enhances the aesthetic appeal of ceramic surfaces but also improves the overall durability and quality of the finished product.

The advanced abrasive technology embedded in these tools ensures efficient material removal while maintaining a superior level of control over the polishing process. By optimizing tool efficiency, Diamond Lappato Abrasives offer a reliable solution for achieving precise surface treatments in various industrial applications.

Abrasive materials like alumina, silicon carbide, zirconia alumina, ceramic aluminum oxide, and cubic boron nitride (CBN) each possess unique characteristics that make them suitable for specific applications in surface treatment. Understanding the properties of these abrasives, such as hardness, toughness, and thermal conductivity, is crucial for selecting the most appropriate material to achieve desired surface finishes.

Alumina, also known as aluminum oxide, is a versatile abrasive material widely recognized for its exceptional hardness and durability in ceramic surface treatment applications.

Alumina's material properties, including its hardness and wear resistance, contribute significantly to its effectiveness in ceramic polishing, surface treatment, and the development of high-precision tools. Understanding these characteristics is crucial for optimizing abrasive technology in various industrial applications.

Having discussed the exceptional hardness and durability of alumina in ceramic surface treatment applications, the focus now shifts to exploring the distinctive characteristics of Silicon Carbide as an abrasive material. Silicon Carbide is known for its excellent abrasive properties, making it highly effective in material removal processes. Its cutting efficiency is exceptional, resulting in smooth surfaces and high surface quality. Silicon Carbide abrasives are favored for their long tool life, providing consistent performance over extended periods. The table below highlights the key characteristics of Silicon Carbide abrasives:

| Characteristics | Silicon Carbide Abrasives |

|---|---|

| Abrasive Properties | High |

| Cutting Efficiency | Excellent |

| Surface Quality | Smooth |

| Material Removal | Efficient |

| Tool Life | Long-lasting |

Zirconia, recognized for its exceptional toughness and heat resistance, is a versatile abrasive material commonly used in various surface treatment applications.

Zirconia alumina stands out in the realm of abrasive materials due to its ability to withstand high temperatures and provide excellent durability in ceramic applications. When it comes to surface treatment, the use of zirconia alumina ensures efficient and effective polishing techniques, resulting in refined finishes that meet industry standards. This abrasive material caters to the needs of professionals seeking control and precision in their surface treatment processes.

Ceramic aluminum oxide, a highly versatile abrasive material, is known for its exceptional hardness and durability in a variety of surface treatment applications. Its characteristics make it ideal for ceramic polishing, precision grinding, and ceramic finishing.

When used in abrasive tools, ceramic aluminum oxide provides efficient material removal while maintaining a consistent surface quality. The abrasive material's toughness and wear resistance ensure longevity, making it a cost-effective choice for industrial applications requiring precision in surface treatment.

Whether in manufacturing processes that demand accuracy or in applications where a fine finish is essential, ceramic aluminum oxide offers the control and reliability needed to achieve desired results efficiently.

Renowned for its exceptional hardness and precision in surface treatment applications, Cubic Boron Nitride (CBN) stands out as a top choice among abrasive materials. CBN offers unparalleled advantages in various industries due to its unique characteristics.

CBN's superior properties make it a preferred material for demanding tasks where precision and durability are essential, ensuring optimal performance in a wide range of applications.

A highly regarded abrasive material known for its exceptional hardness and precision in surface treatment applications is diamond. Diamond tools are at the forefront of abrasive technology, offering unparalleled performance in ceramic polishing, surface finishing, and precision cutting.

The inherent characteristics of diamonds, such as their extreme hardness and durability, make them ideal for achieving superior results in the most demanding surface treatment tasks. When it comes to ceramic surfaces, diamond abrasives excel in providing a flawless finish and precise cuts, meeting the high standards expected in various industries.

The use of diamond abrasives ensures efficient material removal, reduced processing times, and enhanced productivity, making them indispensable in achieving top-notch surface quality.

Diamond Lappato abrasives offer exceptional surface quality, versatility, efficient material removal, long tool life, and consistent performance. These advantages make them ideal for achieving a suitable gloss without grinding scratches, ensuring high working efficiency and sharpness while avoiding tile breakage.

Moreover, their durability prevents segment cracking or dropping during operation, enhancing overall productivity and quality in ceramic surface treatment.

Exhibiting unparalleled efficiency in refining ceramic surfaces, the utilization of Diamond Lappato Abrasives ensures a level of precision that sets a new standard in surface quality. When it comes to exceptional surface quality, this abrasive tool excels in various aspects:

Through the art of polishing ceramics, Diamond Lappato Abrasives deliver a level of excellence that transforms the ceramic surface into a realm of perfection.

The effectiveness of these abrasive tools in enhancing ceramic surfaces is unmatched, providing users with control over the final product's quality and precision.

In the realm of ceramic surface treatment, the versatility of Diamond Lappato Abrasives emerges as a key factor in enhancing the precision and quality of finishes achieved. The versatility benefits of these abrasives allow for a wide range of surface treatment options, catering to various ceramic applications with precision polishing techniques.

This adaptability enables professionals to achieve different surface finishes, from matte to high gloss, with ease and accuracy. Diamond Lappato Abrasives' ability to work effectively on different types of ceramic materials showcases the advancements in abrasive technology, providing a reliable solution for diverse surface treatment needs.

The efficiency of material removal facilitated by Diamond Lappato Abrasives underscores their distinct advantages in ceramic surface treatment. When considering the benefits of these abrasives, the following points highlight their significance:

In the realm of ceramic polishing and surface treatment, the unmatched performance of Diamond Lappato Abrasives, especially in achieving a lappato finish, sets them apart as indispensable tools for those seeking optimal control and high-quality results.

Enhancing operational efficiency and cost-effectiveness, Diamond Lappato Abrasives boast an extended tool life that significantly benefits users in the ceramic surface treatment industry. The durability factor of these abrasives ensures long tool longevity, wear resistance, and extended lifespan, providing consistent and long-lasting performance. This extended tool life reduces the frequency of tool replacements, minimizing downtime and increasing productivity. Users can rely on Diamond Lappato Abrasives for their robustness and ability to maintain effectiveness over an extended period, ultimately leading to cost savings and enhanced operational control.

| Advantages of Diamond Lappato Abrasives | |

|---|---|

| Tool Longevity | High |

| Wear Resistance | Excellent |

| Extended Lifespan | Prolonged |

| Durability Factor | Strong |

| Long Lasting Performance | Consistent |

Boasting an extended tool life that ensures durability and wear resistance, Diamond Lappato Abrasives consistently deliver high performance in ceramic surface treatment applications. When it comes to achieving exceptional results, these abrasives stand out due to:

With a focus on abrasive consistency, Diamond Lappato Abrasives guarantee a superior ceramic tile finish that meets the highest standards of quality performance. This level of consistency empowers users who seek precise control over their surface treatment processes, making these abrasives a preferred choice for professionals aiming for impeccable results.

Precision and reliability are key factors to consider when sourcing Diamond Lappato Abrasives for ceramic surface treatment applications. When looking for these specialized tools, it is essential to turn to reputable diamond lappato suppliers and manufacturers who excel in providing high-quality ceramic polishing tools for various surface treatment techniques. Companies such as Surfaces Group, Basair Diamond Tools, and Mec Abrasives are known for their precision abrasives tailored to meet the demands of professionals in the ceramic tile industry.

These suppliers offer a diverse range of lappato abrasive products designed to enhance the efficiency and effectiveness of surface treatment processes. By understanding the abrasive material properties and the specific requirements of their clients, these manufacturers ensure that their diamond lappato abrasives deliver consistent and superior results. Choosing the right supplier for diamond lappato abrasives is crucial for achieving optimal outcomes in ceramic surface treatment applications, making it imperative to partner with trusted industry leaders known for their expertise and quality products.

Just as a maestro wields a baton to orchestrate a symphony, diamond lappato abrasives can finesse a variety of materials like metal for polishing, glass for engraving, stone for shaping, wood for finishing, and plastic for smoothing.

Diamond lappato abrasives offer versatility for both industrial and residential applications. They provide custom finishes, are compatible with various surfaces, and have manageable maintenance requirements. Their application versatility makes them a preferred choice for controlled environments.

Abrasives longevity varies based on usage intensity. Typically, diamond lappato abrasives last 100-200 hours before replacement is needed due to wear and tear. Regular durability assessment and adherence to a maintenance schedule can optimize their lifespan.

When using diamond lappato abrasives, it is crucial to ensure proper ventilation to minimize exposure to harmful particles. Protective gear such as goggles and gloves must be worn. Adequate training is required, along with regular maintenance checks and knowledge of emergency procedures.

When considering precision finishing and achieving surface smoothness on curved or irregular surfaces, diamond lappato abrasives offer versatile abrasive applications. Utilizing specialized polishing techniques, these tools can effectively enhance the surface quality even on challenging contours.

In conclusion, diamond lappato abrasives are essential tools for precision surface treatment of ceramics. With their unique properties and characteristics, these abrasives work effectively to achieve smooth and polished surfaces.

The applications of diamond lappato abrasives are vast, making them a valuable asset in various industries. The advantages of using these abrasives are numerous, providing high-quality results and efficiency in surface treatment processes.

For those in need of diamond lappato abrasives, finding them is easily accessible through trusted suppliers.

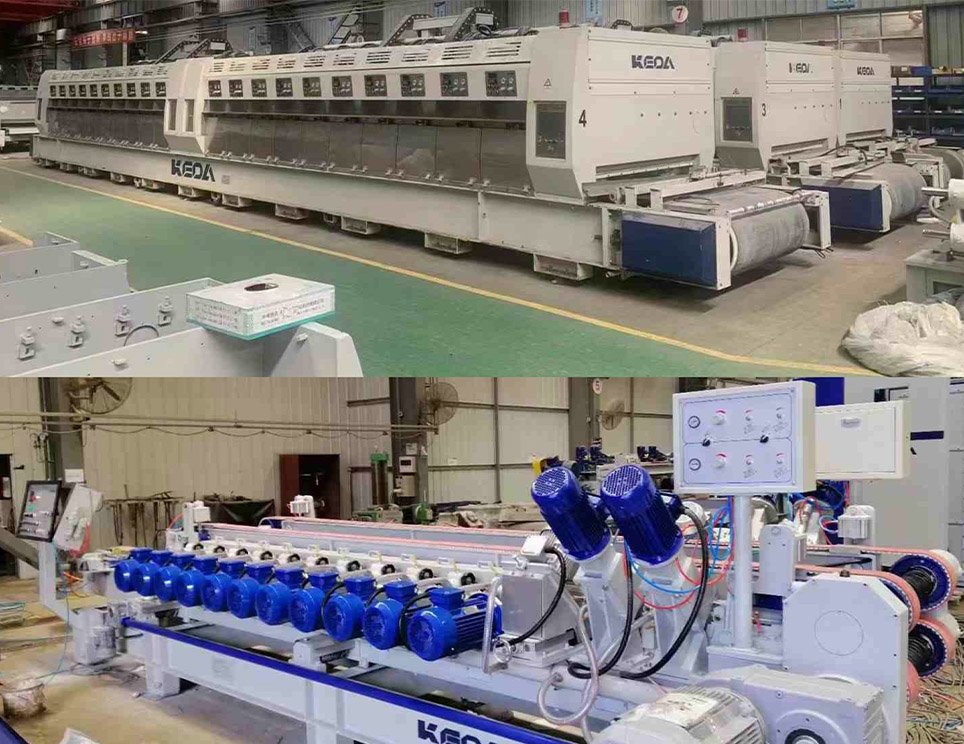

GINGONG in China offers high-quality diamond polishing and edge grinding tools alongside ceramic machinery accessories. Our integrated solutions cater to individual needs, ensuring optimal performance and efficiency. We lead the industry in ceramics polishing, emphasizing effectiveness, cost control, and environmental sustainability. With "Sanmo" machines and meticulous attention to detail, GINGONG delivers top-notch abrasive products, setting the standard for excellence.

Contact us for a free quote of your ideal Diamond Lappato Abrasive for Ceramics!