Understanding the nuances of grinding wheels is a fundamental aspect of various industries where precision and efficiency are paramount.

From the initial selection process to the intricate applications they are designed for, the world of grinding wheels is a complex yet essential one.

Different types of wheels cater to specific needs, and the choice of abrasive material can significantly impact the outcome of a grinding task.

As we navigate through the intricacies of these essentials, it becomes evident that a systematic approach is necessary for optimal results.

Grinding wheels play a crucial role in various metalworking applications. Understanding the purpose of these wheels, how to identify the right one for the job, and the key functions they serve are essential for efficient grinding operations.

From removing excess material to preparing surfaces for welding, grinding wheels are versatile tools that are indispensable in many workshops.

A fundamental component of industrial machinery, grinding wheels are essential tools utilized in abrasive machining operations to shape and refine various materials.

Having established the significance of grinding wheels in industrial machinery for shaping and refining materials, understanding the purpose of grinding unveils the intricate role these tools play in abrasive machining operations. Grinding benefits encompass improved surface precision, enhanced dimensional accuracy, material versatility, environmental advantages, and productivity enhancement.

This process ensures a smooth and uniform surface finish, critical for various applications, while also guaranteeing precise and consistent dimensions, particularly crucial in industries with tight tolerances. The ability to work on a wide range of materials adds to its value across diverse sectors.

Additionally, grinding's eco-friendly aspects, generating less waste and requiring less energy, contribute to its appeal as an efficient and sustainable manufacturing method.

When selecting the appropriate grinding tool for a specific task, it is crucial to consider the type of grinder being utilized and the intended application to ensure optimal performance and efficiency.

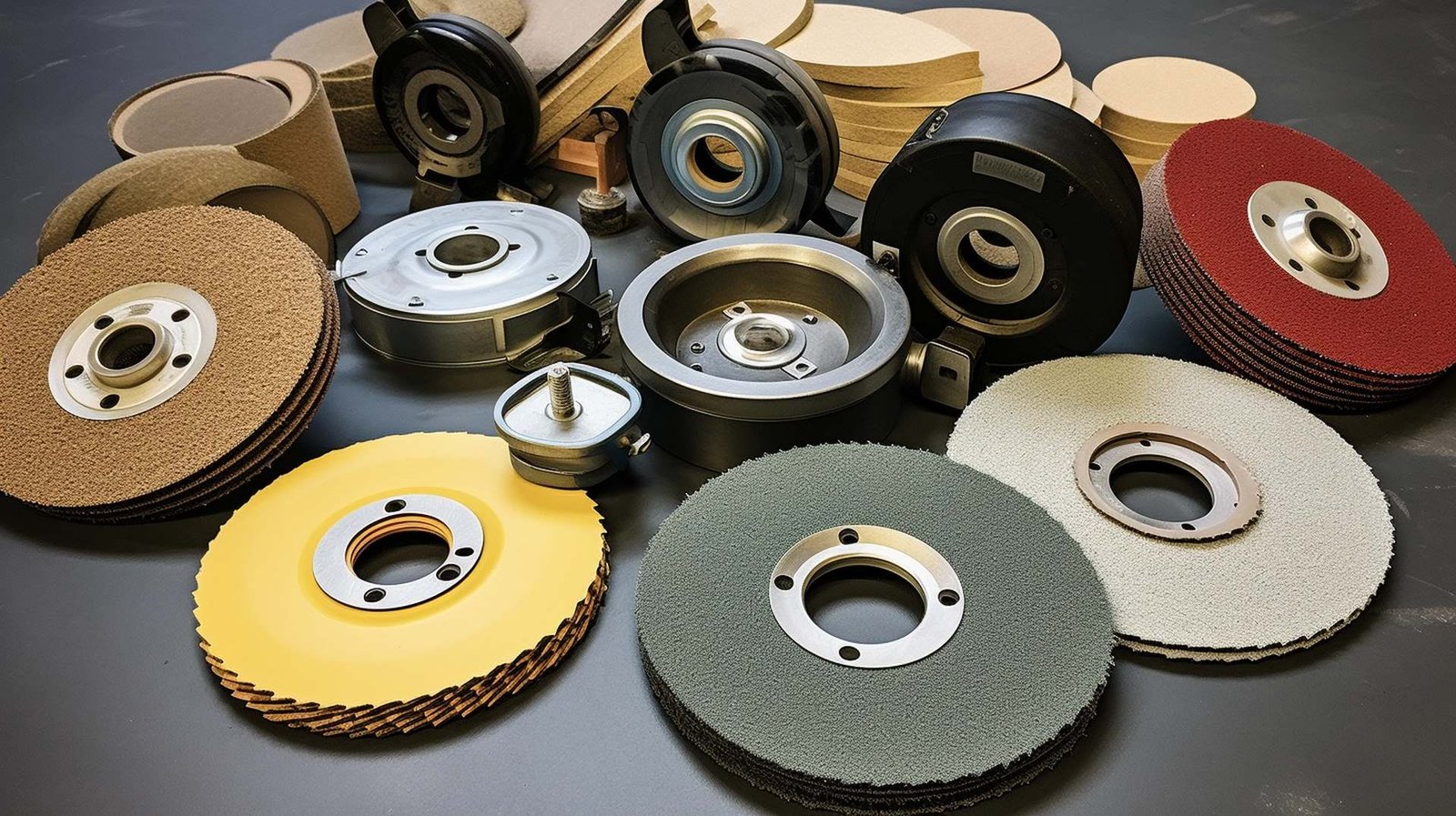

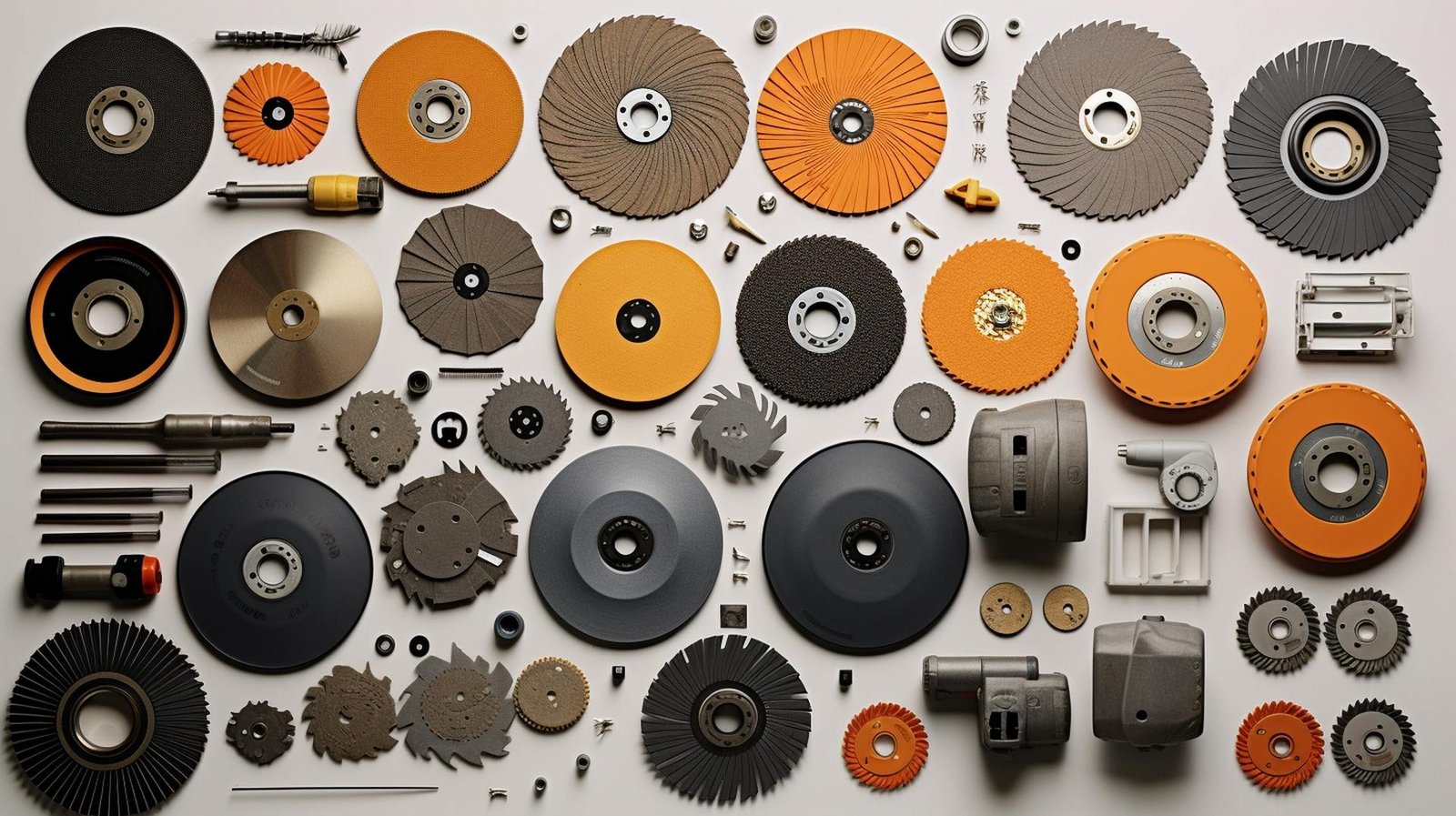

Various types of grinders are available, including handheld grinders like angle grinders, die grinders, linear grinders, and power drills with suitable attachments. Angle grinders, the most commonly used, grind at an angle, while die grinders are capable of cutting or grinding axially. The grinding tool itself can vary, with options like disc wheels, which are mounted on a plate for side grinding, and dish wheels, commonly used for cutter sharpening.

Understanding the different grinding tools and wheels available can help users select the most suitable option for their specific grinding needs.

Best For: Users in need of a versatile grinding tool for various applications in metalworking.

Pros:

Cons:

When it comes to angle grinder wheels, there are various types designed for specific purposes. Grinding wheels are ideal for general grinding tasks, while cut-off wheels are perfect for slicing through metal.

Flap wheels are versatile and effective for finishing work, wire wheels are great for cleaning, and diamond cutting wheels excel in cutting hard materials.

Various types of angle grinder wheels are designed to cater to specific grinding needs and are carefully selected based on the requirements of the task at hand. When considering grinding wheel materials, design considerations, and applications, it is crucial to keep in mind the following factors:

Cut-off wheels, distinguished by their thin design, are essential tools used for making precise cuts in metal bars and sheets. When using cut-off wheels, safety precautions are crucial due to their thinness, which can lead to shattering if bent incorrectly. Different thicknesses of wheels offer varying benefits: thinner discs allow for quicker cuts but are more brittle, while thicker discs are stronger and less likely to warp.

These wheels are compatible with cutting various metal pieces like bars, tubes, and sheet metal. To maintain wheel integrity and safety, proper wheel maintenance is necessary. Precision cutting techniques are required when using cut-off wheels to ensure accurate and clean cuts, especially when cutting out welds or shortening bolts.

Flap wheels, a type of angle grinder wheel, offer a unique approach to providing a finer finish to projects compared to traditional grinding wheels. These wheels consist of multiple overlapping abrasive sheets known as flaps, allowing for a diverse range of applications.

Here are essential points to consider:

When selecting flap wheels, opt for higher grit numbers for smoother finishes. Employ specific finishing techniques such as controlled pressure and consistent movements for optimal results.

Wire wheels, like flap wheels, are essential attachments for angle grinders, offering a distinct functionality in surface preparation and finishing processes. The benefits of wire wheels lie in their ability to quickly remove rust, polish hard metals, and strip paint effectively.

However, caution must be exercised when using them on softer materials to avoid surface scratches. Safety is paramount when using wire wheels, requiring proper eye protection and ensuring secure attachment to the angle grinder. Maintenance involves regular inspection for wear and tear, replacing worn wires promptly.

Techniques for optimal use include adjusting the speed settings on the grinder and maintaining a steady hand. Wire wheels find applications in various industries for tasks requiring precision and efficiency.

Diamond cutting wheels, known for their exceptional durability and cutting efficiency, are indispensable tools for a wide range of industrial applications. When considering diamond wheel benefits, cutting efficiency stands out as a primary advantage. Their longevity advantages are evident in their hardened design, with the cutting rim determining durability.

Application versatility is a key feature, allowing for use on tough materials like masonry or stone. Moreover, the option for wet vs dry cutting provides flexibility in various working conditions. With diamond cutting wheels, users can expect precise and efficient cutting performance, making them essential tools for industrial tasks that demand control and reliability.

Paint stripping wheels, commonly known as strip discs, offer a practical solution for efficiently removing paint from various surfaces without causing damage. These wheels are ideal for surface preparation, paint removal, surface restoration, coating removal, and surface refinishing.

Unlike wire wheels, strip discs are gentle on softer materials like wood, soft metals, and fiberglass, ensuring the surface remains unscratched during the paint removal process. The poly-fiber material used in strip discs makes them well-suited for delicate surfaces and also effective in removing epoxy and other residues.

When tackling tasks that require precision and control, such as paint stripping, strip discs provide a reliable option for achieving a clean and smooth surface without compromising the integrity of the material beneath.

Concrete grinding wheels are essential tools for tough materials like concrete, coming in various shapes and forms to handle demanding surfaces effectively.

They are versatile and can handle materials such as masonry, granite, marble, and stone. Specially designed for tasks like concrete polishing, surface preparation, and material removal.

These wheels often incorporate diamond tools for enhanced performance and durability, utilizing advanced grinding techniques.

It is crucial to monitor wear and tear and replace them promptly to maintain efficiency and safety. Following proper safety procedures and matching disc size and RPM of the angle grinder is essential to prevent damage and potential injuries.

When selecting a grinding wheel, several factors come into play, such as bonds, wheel shapes, abrasive material, grain size, and wheel grade.

The bond type affects the wheel's efficiency and cutting characteristics, while the wheel shape determines its application suitability.

Additionally, the abrasive material, grain size, and wheel grade play crucial roles in achieving the desired finish and performance for specific grinding tasks.

Selecting the appropriate grinding wheel for a specific application requires careful consideration of various factors, with bonds playing a crucial role in determining the wheel's performance. When evaluating bonds, the following aspects are essential for optimal wheel selection:

Considering factors like bond strength and compatibility with the workpiece material is key to ensuring a successful grinding operation.

Understanding the various wheel shapes is essential when choosing a grinding wheel for specific applications, as different shapes offer distinct advantages based on the task at hand. Wheel shapes: practical applications are crucial in determining the efficiency of material removal and surface finish.

When selecting a wheel, understanding abrasive grains is vital, as it affects the cutting ability and durability of the wheel. Wheel geometry considerations, such as diameter and thickness, play a significant role in achieving precise results during grinding operations.

Performance enhancing modifications like advanced bonding systems and wheel structures can optimize grinding performance. Innovation in wheel design continues to drive improvements in efficiency and precision, catering to the evolving needs of industries.

Considering the abrasive material is fundamental in determining the effectiveness and performance of a chosen grinding wheel for specific applications. When selecting the abrasive material, several factors must be taken into account:

Grain size plays a crucial role in the performance and precision of a grinding wheel for various applications. The size of the abrasive grains on a grinding wheel significantly impacts key factors such as grinding efficiency, material removal, surface finish, and tool wear. The grain size distribution refers to the range of sizes present in the grinding wheel, affecting how effectively it can remove material and achieve the desired surface quality. Finer grains generally result in a smoother finish but may wear out faster, while coarser grains excel at rapid material removal but can leave a rougher surface. Selecting the optimal grain size is essential to balance these factors and achieve the desired grinding outcome.

| Grain Size | Effects |

|---|---|

| Fine | Smoother finish, lower material removal rate |

| Coarse | Faster material removal, rougher finish |

The selection of the appropriate wheel grade is a critical factor in determining the performance and longevity of a grinding wheel. It builds upon the foundation laid by the grain size's impact on grinding efficiency and surface quality. When considering wheel grade, focus on:

Choosing the right wheel grade based on these factors ensures efficient cutting, improved surface quality, and enhanced heat resistance during grinding operations.

Strategic spacing between abrasive grains in a grinding wheel significantly influences its cutting efficiency and surface finish. When selecting a grinding wheel, factors such as grain distribution, size, structure, orientation, and sharpness play a crucial role in determining the wheel's performance. The table below summarizes the impact of these grain characteristics on the grinding process:

| Grain Characteristic | Influence on Grinding Wheel Performance |

|---|---|

| Grain Distribution | Uniform distribution ensures consistent cutting action. |

| Grain Size | Larger grains are suited for heavy material removal, while smaller grains provide finer finishes. |

| Grain Structure | Closed structures offer higher material removal rates, while open structures are better for cool cutting. |

| Grain Orientation | Randomly oriented grains result in a versatile wheel for various applications. |

| Grain Sharpness | Sharp grains are effective for precise cutting, but may wear faster. |

When considering a grinding wheel for a specific application, the wheel bond is a critical factor to evaluate for optimal performance. It directly affects grinding efficiency, wheel durability, and heat resistance. Here are key considerations related to wheel bond:

Selecting a wheel bond with appropriate heat resistance and material compatibility is essential for achieving the desired results in precision grinding applications.

For optimal grinding performance, selecting the right grinding wheel involves considering various factors to match the wheel effectively to the specific task at hand. Task compatibility and material removal are crucial aspects to evaluate when choosing a wheel.

The wheel grit plays a significant role in determining the surface finish of the workpiece. Monitoring heat generation and wheel wear is essential to ensure the longevity of the wheel and maintain grinding efficiency.

Implementing safety precautions and regular wheel maintenance practices are imperative for safe and effective grinding operations. By carefully assessing these factors, users can maximize the performance of the grinding wheel while achieving the desired results in their grinding applications.

Abrasive materials play a crucial role in determining the cutting properties of grinding wheels. Materials like aluminum oxide, silicon carbide, ceramic, diamond, and cubic boron nitride each offer unique characteristics and are suited for specific applications.

Understanding the differences between these abrasive materials is essential for selecting the right grinding wheel for the desired task.

Aluminum oxide (A) is a commonly used abrasive material in grinding wheels due to its high hardness and excellent cutting ability. When considering aluminum oxide for grinding applications, several key points should be taken into account:

Silicon carbide (S) is a widely utilized abrasive material in grinding applications due to its exceptional hardness and abrasive properties. Its advantages include high thermal conductivity, low density, and excellent wear resistance, making it suitable for grinding materials like non-ferrous metals and non-metallic substances.

However, silicon carbide's limitations lie in its brittleness, which may lead to fracturing under high pressure. When incorporated into grinding wheel composition, silicon carbide enhances cutting ability and provides finer surface finishes. Its applications range from precision grinding of hardened steels to stone, glass, and ceramics.

To maintain optimal performance, proper grinding wheel maintenance and care are essential. Compared to other abrasive materials, silicon carbide offers unique benefits such as faster cutting rates and the ability to grind harder materials effectively.

Ceramic materials are highly regarded in the realm of grinding wheel essentials for their exceptional durability and heat resistance. When considering ceramic abrasives in grinding wheel materials, several key points come to light:

Renowned for their unparalleled hardness and exceptional cutting capabilities, diamond abrasives (D, MD, SD) stand out as a top choice in the realm of abrasive materials for grinding applications. Diamond performance is unmatched, offering high precision and efficiency during grinding processes. The material durability of diamond abrasives ensures a longer lifespan, contributing to cost-effectiveness. Grinding efficiency is significantly enhanced when utilizing diamond abrasives due to their superior hardness and wear resistance. Achieving a superior surface finish is made possible by the fine edges and abrasive properties of diamonds. Additionally, the tool longevity associated with diamond abrasives minimizes the need for frequent replacements, making them a reliable and efficient choice for precision grinding tasks.

| Diamond Abrasives | Performance | Durability | Efficiency |

|---|---|---|---|

| Diamond (D, MD, SD) | High | Long-lasting | Superior |

Cubic boron nitride (CBN) is a highly efficient abrasive material known for its exceptional hardness and cutting performance in precision grinding applications. When considering CBN for your grinding needs, here are some key points to keep in mind:

For more in-depth understanding, let's delve into a comparison between CBN and diamond, explore essential CBN wheel maintenance tips, discuss effective CBN grinding techniques, and highlight crucial safety precautions when using CBN wheels.

In the realm of grinding applications, the thorough examination and evaluation of system dynamics play a pivotal role in optimizing efficiency and precision. Energy consumption, material removal, surface finish, heat generation, and grinding efficiency are key factors that must be meticulously analyzed to enhance the overall performance of the grinding process.

Understanding the energy consumption patterns within the system is crucial for cost-effectiveness and sustainability. Efficient material removal is essential for achieving the desired shape and dimensions of the workpiece. The surface finish is a critical indicator of the grinding quality and must be carefully controlled to meet specifications.

Heat generation can impact the material properties and tool wear, making it vital to manage effectively. Ultimately, the holistic assessment of these elements contributes to maximizing grinding efficiency, ensuring that the system operates at its peak performance levels with minimal waste and optimal output.

Grinding wheels are not typically used for polishing or finishing applications. They are designed for material removal and surface preparation in metal fabrication, automotive restoration, and DIY projects. Finer abrasives like polishing wheels are more suitable for jewelry making.

To determine the correct speed for a grinding wheel, consider the wheel diameter, material compatibility, and manufacturer recommendations. Optimal performance is achieved when the grinding speed aligns with these factors, ensuring efficiency and safety in operations.

When using a grinding wheel, it is essential to follow safety precautions. This includes wearing proper attire, using eye protection, ensuring machine guards are in place, positioning yourself correctly, and conducting a hazard assessment to prevent accidents.

Grinding wheels can indeed be used for sharpening tools or blades such as knives, scissors, and chisels. They offer precision and efficiency in restoring sharp edges. When used correctly, grinding wheels can enhance productivity and prolong the lifespan of cutting instruments.

Proper storage is essential for extending the lifespan of grinding wheels. Store them in a dry area away from moisture and extreme temperatures. Regularly inspect for damage and clean off debris. Following these maintenance techniques enhances longevity.

In the world of grinding wheels, each blade represents a unique tool for shaping and refining materials. Just as a painter carefully selects their brushes to create a masterpiece, a craftsman must choose the right grinding wheel for their work.

The art of grinding is a delicate dance between precision and power, where the right wheel can unlock hidden potential and bring forth beauty from rough surfaces. Choose wisely, for the grinding wheel is the artist's brush in the world of craftsmanship.